Discover the Latest Innovation in Acrylic Cutting with Fiber Laser Technology

By:Admin

Introduction:

In recent news, the cutting-edge technique of fiber laser cutting has emerged as a game-changer in the acrylic industry. With its ability to precisely cut acrylic materials with unparalleled accuracy and efficiency, fiber laser cutting has revolutionized the manufacturing and design processes for acrylic products. This article aims to delve into the world of fiber laser cutting and its impact on the acrylic industry, showcasing its benefits and potential applications.

What is Fiber Laser Cutting?

Fiber laser cutting is a technology that utilizes a high-powered laser beam to cut through various materials, including acrylics. Unlike conventional laser cutting methods, fiber laser cutting employs a solid-state laser source that uses optical fibers to generate and deliver the laser beam to the cutting head. This approach allows for enhanced cutting speeds, higher precision, and improved cost-efficiency.

The Company Leading the Way:

Headquartered in {Company's location}, {Company's name} has emerged as one of the leading industry players in the application of fiber laser cutting technology. With extensive experience in materials processing and a commitment to innovation, {Company's name} has pioneered advancements in acrylic cutting, providing customers with unparalleled solutions for their manufacturing needs. By leveraging the power of fiber laser cutting, the company has propelled acrylic processing to new heights.

Benefits of Fiber Laser Cutting Acrylic:

1. Precise and Intricate Cuts: Fiber laser cutting enables the production of intricate designs, detailed engravings, and smooth edges on acrylic material, ensuring high-quality finished products.

2. High Speeds: Fiber lasers boast exceptional cutting speeds, resulting in improved production efficiency and reduced lead times. This allows manufacturers to meet increasing demand and stay competitive in the market.

3. Minimal Material Waste: Fiber laser cutting maximizes material utilization due to precise cutting paths. This not only reduces raw material costs but also promotes sustainability by minimizing waste generation.

4. Versatility: Fiber laser cutting technology is highly versatile, capable of cutting acrylic sheets of various thicknesses (up to a certain limit) with equal precision. This versatility empowers manufacturers to explore new design possibilities and expand their product offerings.

Potential Applications:

The applications of fiber laser cutting in the acrylic industry are vast and diverse. They include but are not limited to:

1. Signage and Displays: Fiber laser cutting allows for the fabrication of intricate letters, logos, and shapes for signage and advertising displays, ensuring eye-catching and visually appealing end products.

2. Architectural Components: From decorative elements to functional components like windows and dividers, fiber laser cutting enables the creation of custom-designed acrylic pieces that add a touch of elegance to both residential and commercial buildings.

3. Acrylic Jewelry and Accessories: Jewelry designers have embraced fiber laser cutting to craft unique and intricate acrylic statement pieces, exploring diverse shapes and patterns that cater to individual tastes.

4. Electronics and Industrial Components: Fiber laser cutting ensures precise and consistent shapes for intricate electronic parts and industrial components, providing manufacturers with the accuracy required for seamless integration and functionality.

Conclusion:

In summary, fiber laser cutting technology has ushered in a new era in acrylic cutting, as its numerous advantages continue to reshape the manufacturing landscape. With enhanced precision, increased production speeds, reduced material waste, and its versatility, fiber laser cutting offers limitless possibilities for the acrylic industry. As companies like {Company's name} lead the way, the future of acrylic cutting looks promising, paving the path for exceptional quality, beautiful designs, and efficient manufacturing processes.

Company News & Blog

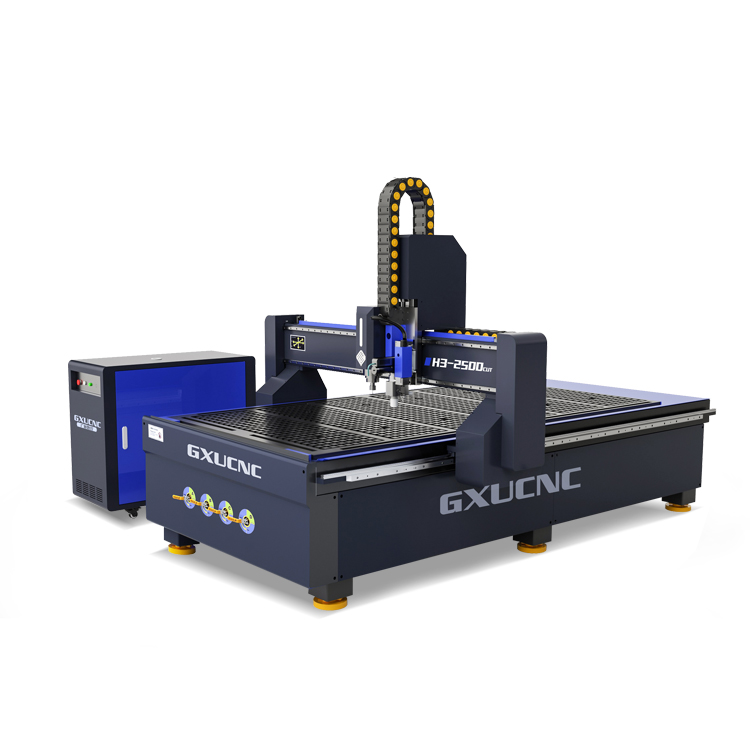

Unlock Your Woodworking Potential with a High-Quality CNC Router - Tribune Online A computer-controlled router tool, known as a CNC router, can make intricate and accurate cuts in a range of materials like wood, plastic, metal, and even decorative items.

Maximize Your Woodworking Potential with a Top-Quality CNC RouterIf you are a woodworking enthusiast, you know how important precision and accuracy are in creating beautiful and functional pieces. A CNC router may just be the tool you need to take your woodworking skills to the next level. A CNC (computer numerical control) router is a cutting machine that uses computer programs to produce intricate and precise cuts.A 12x12 CNC router is the perfect size for home woodworking projects. It allows you to cut and carve various materials, including wood, glass, plastic, and even metals, with remarkable precision. Additionally, it is a versatile machine that can produce items ranging from decorative pieces to functional furniture.Benefits of a CNC Router in WoodworkingBetter Precision: One of the most significant advantages of using a CNC router in woodworking is the level of precision it offers. The use of digital technology and computer programs eliminates human errors, producing precise cuts and carvings.Increased Efficiency: With a CNC router, you can produce multiple and identical pieces in a shorter period. This is because a computer program controls the machine, allowing you to work on multiple pieces simultaneously without having to measure and mark each piece several times.Enhanced Creativity: A CNC router allows you to achieve intricate and complex designs easily, giving you the freedom to exercise your creativity and imagination fully.Ease of Use: A 12x12 CNC router is straightforward to operate, even for beginners. Once you have a design, all you need to do is upload it to the machine via a computer, and the machine does the rest.Things to Consider When Buying a CNC RouterSize: The size of a CNC router determines the size of the material you can work on. Before purchasing a router, consider the size of the projects you intend to undertake and choose a machine that accommodates your needs.Power: A more powerful router translates to faster cutting speeds. However, a more powerful router also means higher costs. Consider your budget and the type of projects you intend to work on when choosing a router.Cost: CNC routers come in different sizes, powers, and prices. While it may be tempting to purchase the cheapest option, it is essential to weigh the performance and quality you get against the price.ConclusionA CNC router is a valuable tool for any woodworking enthusiast. It allows you to create precise and detailed cuts in various materials, producing high-quality functional and decorative pieces. A 12x12 CNC router is an excellent option for home woodworking projects as it is versatile, easy to use, and takes up minimal space.

Discover the Powerful Capabilities of a High-Power Laser Cutter!

Title: Cutting-Edge Laser Technology Revolutionizes Manufacturing ProcessesIntroduction: In a groundbreaking development, a prominent manufacturing company has introduced its latest innovation, a state-of-the-art 100W Laser Cutter. This cutting-edge technology is set to redefine traditional manufacturing processes, showcasing the company's commitment to innovation, precision, and efficiency in the ever-evolving industry.With its fine-tuned laser beam, this new machine has the potential to transform various industries, including automotive, aerospace, electronics, and textile. Offering a myriad of possibilities, this news article will explore the capabilities and impact of this 100W Laser Cutter, as well as highlight the key features and competitive advantage it brings to the market.1. Importance of Laser Cutters in Manufacturing:Laser cutting technology has long been recognized as vital for precision cutting, engraving, and etching in manufacturing. From intricate designs to mass production, laser cutters offer several advantages including accuracy, speed, flexibility, and cost-efficiency. The introduction of a 100W Laser Cutter takes these defining characteristics one step further.2. Key Features and Specifications:The company's 100W Laser Cutter boasts several innovative features that enhance its performance and versatility. Equipped with a highly powerful 100W laser beam, it can precisely cut through a wide range of materials, including metals and non-metals. The machine's advanced control system and cutting-edge software ensure precise cuts, reduced material wastage, and increased production efficiency.Additionally, the laser cutter offers a large working area, allowing for the processing of various-sized materials. With exceptional speed and accuracy, this cutter can produce complex, intricate designs with unparalleled finesse, revolutionizing the manufacturing process.3. Enhanced Efficiency and Precision:The 100W Laser Cutter has set new benchmarks in manufacturing by greatly improving efficiency and precision across various applications. Traditional cutting processes often require secondary operations, such as deburring or polishing, which increase both time and cost. However, this laser cutter significantly reduces the need for additional finishing, resulting in quicker turnaround times and increased productivity.Furthermore, its high precision eliminates human error, enabling the production of intricate designs and complex shapes with unparalleled accuracy. This advanced laser cutting technology ensures consistent quality and meets the most demanding manufacturing requirements.4. Diverse Applications:The versatility of the 100W Laser Cutter opens a multitude of possibilities across different industries. In the automotive sector, it can produce intricate components with precision, improving overall performance and safety. For the aerospace industry, this laser cutter helps create lightweight materials with complex geometries that enhance fuel efficiency and reduce emissions.In the electronics field, the laser cutter aids in manufacturing microcircuits, connectors, and precision components, ensuring reliability and longevity. Textile manufacturers can leverage this technology for intricate fabric designs, enabling customization and enhancing aesthetic appeal.5. Environmental Impact:Along with its revolutionary capabilities, the 100W Laser Cutter promotes sustainable manufacturing practices. By minimizing material wastage and reducing the need for secondary operations, it significantly contributes to a greener manufacturing process. Additionally, the laser cutting process produces minimal emissions, ensuring a cleaner and safer work environment.Conclusion:The introduction of the 100W Laser Cutter by the company marks a significant milestone in the manufacturing industry. With its powerful laser beam, advanced control system, and impeccable precision, this cutting-edge technology stands at the forefront of transforming traditional manufacturing processes. Its diverse applications, enhanced efficiency, and minimal environmental impact solidify its position as a game-changer in various industries.As the manufacturing sector continues to evolve, this innovation paves the way for increased productivity, improved product quality, and reduced costs. The 100W Laser Cutter truly embodies the company's dedication to innovative solutions, further cementing its position as an industry leader.

Top Tips for Choosing a Wood Cutting Router for Your Projects

Woodworking has changed significantly over the years, and with innovative technology, Wood Cutting Routers have replaced traditional tools and manual labor in the process. These routers are machines that employ rotary tools to cut and shape wood, making them an essential tool in the woodworking industry. With the market becoming more competitive, many companies have released their variation of the tool. However, one brand stands out from the rest - {Brand name}. Their Wood Cutting Routers are the epitome of precision and durability.{Brand name} is a company that has been a cornerstone of the woodworking industry since its inception. They specialize in the creation of high-quality woodworking tools, and their Wood Cutting Routers are no exception. The company is dedicated to providing woodworkers with the highest quality tools, made with precision and designed with durability. In an industry that demands excellence, {Brand name} has built a solid reputation by providing woodworking tools that exceed the expectations of their customers.The {Brand name} Wood Cutting Router is an exceptional tool that has made woodworking more efficient. As opposed to traditional tools that require manual labor, these routers operate using a rotatory tool that allows them to cut and shape wood with supreme precision. The tool's motor is powered by electricity, making it faster and more efficient in completing tasks. The {Brand name} Wood Cutting Router is at the forefront of this technology, making it one of the most popular tools in the industry.One of the benefits of using a {Brand name} Wood Cutting Router is their precision cutting ability. They have a robust motor that provides enough power to make precise cuts, no matter the density of the wood. The tool also comes with a variety of attachments and bits, making it versatile in handling different wood cutting tasks. The router's accuracy makes it an essential tool for carpenters, woodworkers, and DIY enthusiasts.Another feature that sets {Brand name}'s Wood Cutting Router apart is its durability. The company uses high-quality materials such as metal and sturdy plastics in manufacturing their routers, making them long-lasting and resistant to wear and tear. The tool's motor is built to last, and with proper care and maintenance, users can enjoy its services for years.Ease of use is also another feature that makes {Brand name}'s Wood Cutting Router popular amongst woodworkers. The routers have easy-to-use controls, allowing users to operate the tool effortlessly. The tool's design also makes it comfortable to hold, reducing user fatigue and improving efficiency. The router's versatility makes it possible to use on various wood surfaces, ensuring that the user can perform a wide range of cutting and shaping tasks.As technology advances, {Brand name} is continually improving the design and functionality of their Wood Cutting Routers. The latest models come with advanced features such as dust extraction systems that keep the work station clean while reducing operator exposure to wood dust, a significant workplace hazard. The routers also have advanced safety features, including safety switches and automatic speed regulation, protecting users from accidents.In conclusion, the {Brand name} Wood Cutting Router is an exceptional tool that has revolutionized the woodworking industry. The tool's precision, durability, and ease of use make it a popular choice amongst woodworkers. With the company continually improving the design and functionality of their routers, the woodworking industry can only expect more exceptional tools from {Brand name}.

Advanced 5-Axis CNC Router for Precise Woodworking and Carving Applications

Are you looking for a 4-axis CNC router machine that can provide exceptional precision, speed, and reliability while working on various materials? Look no further than the RCF 2560 CNC router from China. This top-of-the-line machine is designed to meet the highest standards of the industry and can deliver unparalleled performance and quality.The RCF 2560 CNC router is a 5-axis machine that offers a massive working area of 2500mm x 6000mm (approximately 98.4in x 236.2in), allowing you to handle large-sized materials with ease. With its advanced 5-axis technology, the machine can move the cutting tool in multiple directions, which makes it perfect for complex and intricate designs. Whether you're working on wood, plastics, composites, or non-ferrous metals, this machine can deliver optimal results.One of the most significant advantages of the RCF 2560 CNC router is its unparalleled speed and precision. The machine is equipped with a powerful spindle and a high-speed servo motor that can deliver up to 24000 RPM, allowing you to work on multiple materials quickly and efficiently. Additionally, the machine's accuracy is ensured by its advanced control system that can adjust the cutting speed and depth according to the material being worked on.Another key feature of the RCF 2560 CNC router is its user-friendly interface. The machine's control system is straightforward to use and allows you to create and edit your designs easily. Additionally, the machine is compatible with various software, making it versatile and adaptable to your needs.In terms of versatility, the RCF 2560 CNC router can be used for a wide range of applications, from furniture making to sign-making to aerospace industry. The machine's ability to cut different materials with exceptional precision and speed makes it a perfect choice for businesses that require high-quality output in a short amount of time.In conclusion, the RCF 2560 CNC router machine is the ideal solution for anyone looking for a 4-axis machine that can handle large-sized materials with exceptional precision and speed. Its user-friendly interface, advanced control system, and versatile applications make it a valuable investment for businesses in various industries. Contact us today to learn more about the RCF 2560 CNC router and how it can benefit your business.

Top 5 Laser Welding Machines for Your Business Needs

article:Laser Welding Machine: The Revolution in Welding TechnologyWelding is an essential process in industrial manufacturing. It involves joining two or more pieces of metal or plastic to create a single component. Traditionally, welding has always been done through arc welding, which is an electric welding process that uses an electrical arc to melt the metal pieces together. However, with the advent of newer technologies, there has been a shift towards laser welding machines, which offer numerous advantages over traditional welding techniques.Laser welding technology is a cutting-edge process that uses a highly-focused laser beam to melt the metal or plastic components together. The laser beam is so precise that it can melt the metal without causing any damage to the surrounding material. This is in contrast to arc welding, which often results in excess heat and damage to the surrounding material. Furthermore, laser welding machines can be automated, making the process faster and more reliable.The laser welding machine offered by the company is a state-of-the-art piece of equipment that has revolutionized the welding industry. This machine is built to the highest quality specifications and offers unparalleled performance. It is designed to weld a wide range of materials, such as aluminum, titanium, stainless steel, carbon steel, and plastic.The laser welding machine uses a specially-designed laser beam that is highly precise and accurate. The beam is focused onto the weld area, creating a small, concentrated heat source. The laser beam can be precisely controlled to match the welding speed and material type, making it ideal for welding components of different thicknesses or shapes.One of the major advantages of the laser welding machine is its ability to produce high-quality welds, with minimal distortion or damage to the surrounding material. This is because the laser beam is so precise that it can melt the metal or plastic without affecting the surrounding components. The result is a clean, smooth, and strong weld. Furthermore, the machine is highly efficient, with a low heat input and minimal material waste.The laser welding machine is also highly versatile, with a wide range of applications. It can be used to weld small, delicate components, such as medical implants or microelectronics. It can also be used to weld larger pieces, such as automotive parts or aerospace components. In addition, the machine can be used to repair or modify existing components, making it ideal for maintenance and repair work.Overall, the laser welding machine is a game-changer in the welding industry. It offers numerous advantages over traditional welding techniques, such as arc welding. These advantages include higher precision, better quality welds, and increased efficiency. Furthermore, the machine is highly versatile and can be used for a wide range of applications. As the manufacturing industry continues to evolve, laser welding technology is likely to become even more prevalent.

The Most Powerful 2000 Watt Laser Cutter for All Your Cutting Needs

article about the latest advancements in laser technology and their impact on manufacturing.The latest innovation in laser technology has been revealed with the unveiling of a 2000-watt laser cutter. This new technology promises to revolutionize the manufacturing industry, offering a fast, efficient and cost-effective solution to cutting a wide range of materials. This new development comes from one of the leading companies in the industry, who have been working tirelessly to develop the latest cutting-edge technology.The use of laser cutting technology has been around for several years, but with the introduction of the 2000-watt laser cutter, it is safe to say that the industry has been taken to a whole new level. This cutting-edge technology is set to have a significant impact on various sectors, including aerospace, defense, automotive, and jewellery. As companies look to seek out top quality products while still maintaining low production overheads, this new technology is set to revolutionize the manufacturing industry.The 2000-watt laser cutter is an exceptional machine that utilizes precise light amplification technology (PLT) to deliver unmatched cutting performance. It has the capability to cut through almost any material, including stainless steel, aluminum, acrylic, plastics, and wood. The technology is so advanced that it can accurately cut intricate designs with great ease and precision.The company behind this new innovation has rightly been dubbed as one of the frontrunners in the industry. They specialize in the production of a wide range of laser cutting machines, and with the introduction of the 2000-watt laser cutter, they have once again proven their commitment to providing their clients with cutting-edge technology.The company is known for its dedication to quality, and the 2000-watt laser cutter lives up to that reputation. The machine has been built with advanced components, which have been carefully selected and rigorously tested to ensure optimal performance.One of the most notable advantages of this technology is its speed. The 2000-watt laser cutter is capable of cutting through thick materials at an impressive rate, making it an ideal solution for manufacturers who require high-volume production. The machine is also designed with maximum efficiency in mind, with a low-power consumption that reduces the risk of overheating and ensures that it is cost-effective in the long run.In addition to its speed and efficiency, the 2000-watt laser cutter comes with several safety features. The machine is designed with advanced safety features that make it easier to use, even for inexperienced operators. This significantly limits the risk of accidents in the workplace, which is why this technology is fast gaining popularity in manufacturing firms across the globe.This latest innovation in laser technology is set to have a significant impact on the manufacturing industry. It is ideal for creating high-quality products in a short period, which is essential in today's fast-paced environment. The 2000-watt laser cutter is expected to be a game-changer for manufacturers, allowing them to streamline their production processes and boost their profits.In conclusion, the introduction of the 2000-watt laser cutter is a testament to the continued advancements in laser technology. The machine is fast, efficient, versatile and safe, making it an ideal solution for manufacturers across various industries. With the increasing demand for top-quality products, manufacturers need to invest in the latest technology to remain competitive. As the demand for the 2000-watt laser cutter continues to grow, it is bound to become the go-to machine for manufacturers looking to achieve a competitive edge.

Affordable 4x4 Table Size CNC Wood Router Now Available for Sale

Title: Affordable 4x4 Table Size CNC Wood Router HTG1313 Available for Woodworking EnthusiastsIntroduction:In the booming industry of woodworking, the importance of efficient and precise machining cannot be understated. CNC wood routers have revolutionized the field by providing unmatched accuracy and versatility. HITEC CNC, a renowned manufacturer and supplier of cutting-edge woodworking machinery, is now offering an affordable 4x4 table size CNC wood router HTG1313 for enthusiasts in the industry.A Versatile and Efficient Solution:The HTG1313 CNC wood router is designed to meet the diverse needs of woodworking professionals and hobbyists alike. With its sturdy construction and impressive capabilities, this machine is capable of handling various tasks with exceptional precision. From intricate carving to complex cutting, the HTG1313 allows craftsmen to effortlessly create stunning and intricate designs on wood.Outstanding Features:The HTG1313 boasts a wide array of features that set it apart from its counterparts. Its 4x4 table size offers ample working space, allowing users to accommodate large workpieces and maximize productivity. The machine utilizes advanced technology to ensure that each cut is executed with precision and finesse, resulting in flawless end products.One of the standout features of the HTG1313 is its user-friendly interface. The intuitive control system empowers users of all skill levels, enabling them to effortlessly navigate through the machine's vast capabilities. Additionally, the machine can be easily customized to match specific requirements, making it a versatile tool for a wide range of woodworking projects.Affordability and Quality Combined:HITEC CNC has established a reputation for delivering high-quality machinery at affordable prices, and the HTG1313 is no exception. By offering this 4x4 table size CNC wood router at a competitive price, the company aims to make advanced woodworking technology accessible to as many enthusiasts as possible. This strategic pricing, combined with HITEC CNC's commitment to quality, makes the HTG1313 an attractive and cost-effective investment.Ease of Maintenance:The HTG1313 is designed for seamless maintenance and longevity. HITEC CNC provides comprehensive after-sales support, including technical assistance and spare parts availability, ensuring that customers can keep their machines in optimal condition. The company's commitment to customer satisfaction extends beyond the initial purchase, adding further value to the HTG1313.Applications and Market Prospects:The HTG1313 caters to a wide range of woodworking applications. Whether it's cabinetry, furniture manufacturing, sign-making, or architectural woodwork, this CNC wood router offers unrivaled accuracy and efficiency. With the increasing demand for customized and intricate woodwork, the market for CNC wood routers continues to grow, presenting a promising future for machines like the HTG1313.Conclusion:HITEC CNC's affordable 4x4 table size CNC wood router HTG1313 is an excellent choice for woodworking enthusiasts seeking a reliable and precise cutting solution. With its advanced features, versatile capabilities, and user-friendly interface, the HTG1313 stands out as a cost-effective investment in the woodworking industry. HITEC CNC's commitment to quality and after-sales support further enhances the value proposition of this remarkable machine. As the demand for CNC wood routers continues to rise, the HTG1313 provides woodworking professionals and hobbyists with the tool they need to take their craftsmanship to new heights.

High-Speed Mini CNC Laser Engraver for DIY Craft - Adjustable Focal Length & PC Software Support, Wood Leather Fabric Paper Cutting & Engraving - 450nm 5.5W Laser

ArrisWeb.com is pleased to announce the release of the 450nm 5.5W Laser Engraving Machine Adjustable Focal Length Support PC Software High Speed Mini CNC Laser Engraver Cutter Precise Carver Printer for DIY Craft. This machine is a versatile tool designed for use by craftspeople and small business owners looking for a reliable, high-speed laser engraving machine.This laser engraver is perfect for cutting and engraving wood, leather, fabric, and paper. The high-speed capabilities provide a quick, efficient process that ensures quality results no matter what you're working on. With an adjustable focal length and support for PC software, you can achieve exceptional precision and control while engraving.The 450nm 5.5W Laser Engraving Machine is a compact and efficient tool that is perfect for crafting and small business environments. It is designed to be user-friendly, making it easy for anyone to use without any prior experience in laser engraving. The machine is also highly customizable, providing users with plenty of options for customizing their designs and projects.The laser engraving machine comes with a range of cutting-edge features that set it apart from other models in the market. The software it uses is easily compatible with various operating systems, making it accessible to a wider range of users. Additionally, its high-precision laser head ensures that your designs are always perfectly aligned and centered, guaranteeing consistently high-quality results.The machine's high-speed capabilities make it much more efficient than traditional engraving tools. The powerful laser can engrave intricate images and designs in seconds, allowing you to complete larger projects faster. This makes the 450nm 5.5W Laser Engraving Machine ideal for small business owners looking to boost their productivity and output.ArrisWeb.com is committed to providing customers with high-quality products, and the 450nm 5.5W Laser Engraving Machine is no exception. The company has built a reputation for producing reliable and efficient tools that deliver outstanding results. Their laser engraving machine has been designed under strict quality control measures to ensure that it meets the highest standards in the industry.One of the biggest benefits of using this laser engraver is its versatility. It can be used to create a wide range of products, including personalized gifts, promotional items, and much more. The machine's ability to engrave on virtually any surface makes it an excellent option for makers looking to work with different types of materials.Overall, the 450nm 5.5W Laser Engraving Machine Adjustable Focal Length Support PC Software High Speed Mini CNC Laser Engraver Cutter Precise Carver Printer for DIY Craft is an excellent investment for anyone interested in laser engraving. Its user-friendly design, combined with its high-speed capabilities and versatility, make it an efficient and reliable tool that delivers outstanding results. With its powerful features, customizable software, and compact design, this laser engraver is an excellent tool for any craftsperson, small business owner, or hobbyist looking for a high-quality, affordable option.

High-Precision Fiber Laser Cutting Machine for Efficient Metal Processing

CNC Fiber Laser Cutting Machine: The Innovation in Metal Cutting TechnologyOver the years, different advancements in technology have been made for different industries. One of the biggest beneficiaries of technological advancements is the manufacturing industry, and specifically the metal cutting industry. With the introduction of CNC Fiber Laser Cutting machines, manufacturers can cut different kinds of metal materials with a high precision and speed like never before.CNC Fiber Laser Cutting machines have gained immense popularity in the manufacturing industry. Companies like Shandong Pengwo Laser Technology Co., Ltd. have been at the forefront of designing and manufacturing CNC Fiber Laser Cutting machines that are efficient, precise, and reliable. The machine uses a fiber laser generator and ball screw moving system that enable it to cut and punch different types of metal materials without compromising on quality.Features of CNC Fiber Laser Cutting Machines1. High Cutting Precision:CNC Fiber Laser Cutting Machines have a high cutting precision that enables them to deliver top-notch end products. The laser is transmitted through a fiber, which ensures that there is no loss of energy, and hence precision cutting is achieved. Whether you need to cut intricate designs or thick metals, CNC Fiber Laser Cutting Machines will deliver.2. High Speeds:The use of advanced fiber laser technology with ball screw moving systems enables CNC Fiber Laser Cutting machines to achieve high speeds while cutting, without compromising the precision. By increasing the production speed, your manufacturing process will become more efficient, and your business will be more profitable.3. Low Maintenance:One of the biggest advantages of installing CNC Fiber Laser Cutting Machines is its low maintenance. Since the laser is transmitted through a fiber, there is no need to adjust or maintain the laser optical path. In contrast, traditional laser cutting machines require frequent maintenance, which can be costly and time-consuming.4. Energy Efficiency:CNC Fiber Laser Cutting Machines have excellent energy efficiency compared to other traditional metal cutting methods. The advanced fiber laser technology used in these machines significantly reduces the amount of energy consumed, which in turn helps to lower your operating costs. It is an environmentally friendly cutting option with no emissions of harmful substances.5. Versatile:CNC Fiber Laser Cutting Machines can cut different types of metals, including steel, stainless steel, aluminum, copper, and brass. This versatility makes them indispensable in the manufacturing process as they offer a wide variety of options to cut different shapes and sizes of metal materials.Conclusion:CNC Fiber Laser Cutting Machines are the latest innovation in the metal cutting industry. They offer a plethora of features that make them indispensable to the manufacturing process. High precision, high speed, low maintenance, energy efficiency, and versatility are some of the unique selling points of CNC Fiber Laser Cutting Machines. By incorporating them into your manufacturing process, you will increase efficiency, profitability, and precision cutting. So, if you are looking for an efficient and reliable way to cut metals, CNC Fiber Laser Cutting Machines are definitely worth considering.