Top Co2 Laser Cutting Machine: Features, Benefits, and Applications

By:Admin

In today's fast-paced world, the manufacturing industry is constantly seeking ways to improve efficiency and productivity, and the latest advancement in laser cutting technology is proving to be a game-changer. Laser Cutting Machine Co2, a leading provider of innovative laser cutting solutions, is at the forefront of this technology revolution and is helping manufacturers around the world stay ahead of the competition.

Laser Cutting Machine Co2 has been a pioneer in the development of CO2 laser cutting machines since its inception. The company's commitment to innovation and excellence has made it a trusted partner for businesses across a wide range of industries, including automotive, aerospace, electronics, and consumer goods.

One of the key advantages of CO2 laser cutting technology is its ability to cut a wide variety of materials with unparalleled precision and speed. Whether it's metal, plastic, wood, or glass, CO2 lasers can effortlessly handle the most complex cutting tasks with ease. This versatility has made CO2 laser cutting machines an indispensable tool for manufacturers looking to streamline their production processes and reduce waste.

Another standout feature of Laser Cutting Machine Co2's laser cutting machines is their superior energy efficiency. Unlike traditional cutting methods, CO2 laser cutting produces minimal waste and consumes significantly less energy, making it an environmentally friendly choice for businesses looking to reduce their carbon footprint.

Furthermore, Laser Cutting Machine Co2's commitment to customer satisfaction is evident in its comprehensive range of laser cutting solutions. From entry-level machines for small businesses to high-end industrial systems for large-scale manufacturers, the company offers a diverse selection of CO2 laser cutting machines to meet the unique needs of its clients.

In addition to its cutting-edge technology, Laser Cutting Machine Co2's dedication to customer support sets it apart from its competitors. The company's team of experienced engineers and technicians provide ongoing training, maintenance, and technical assistance to ensure that its clients get the most out of their laser cutting machines.

As the manufacturing industry continues to evolve, Laser Cutting Machine Co2 remains at the forefront of innovation, constantly pushing the boundaries of what is possible with CO2 laser cutting technology. With a focus on research and development, the company is committed to staying ahead of the curve and delivering cutting-edge solutions that empower manufacturers to achieve new levels of efficiency and productivity.

In conclusion, Laser Cutting Machine Co2 is leading the charge in revolutionizing the manufacturing industry with its state-of-the-art CO2 laser cutting technology. With its unmatched precision, energy efficiency, and commitment to customer satisfaction, the company is a trusted partner for businesses looking to stay competitive in today's fast-paced market. As the demand for high-quality and cost-effective cutting solutions continues to grow, Laser Cutting Machine Co2 is well-positioned to meet the needs of manufacturers across the globe and drive the industry forward into a new era of innovation and success.

Company News & Blog

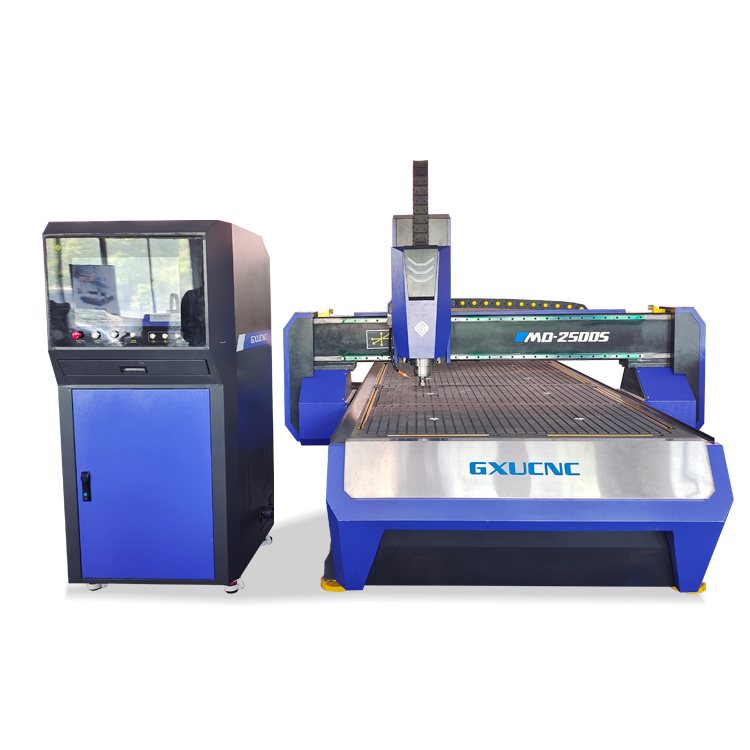

Highly Efficient Wood Cutting Machine for CNC Processing

Woodworking industry has been revolutionized by the introduction of the latest CNC wood cutting machine by a leading manufacturing company. The advanced technology and precision engineering of this machine have set a new benchmark for wood cutting and carving, making it an indispensable tool for modern woodworking businesses.The CNC wood cutting machine is designed to meet the diverse needs of the woodworking industry, offering unparalleled speed, accuracy, and efficiency. Its cutting-edge features enable woodworkers to create intricate designs, fine details, and smooth finishes with utmost perfection. The machine is equipped with a high-speed spindle and advanced cutting tools that ensure clean and precise cuts on various types of wood, including hardwoods, softwoods, and engineered wood products.One of the key highlights of this CNC wood cutting machine is its ability to produce complex 3D designs and engravings with exceptional accuracy. Whether it's creating custom furniture pieces, decorative panels, or architectural elements, the machine delivers flawless results that meet the highest quality standards. Its user-friendly interface and intuitive software make it easy for woodworkers to input designs and execute cutting tasks with minimal effort.The company behind this innovative CNC wood cutting machine has a rich history of manufacturing cutting-edge industrial machinery. With decades of experience and expertise in the field, the company has consistently pushed the boundaries of technological innovation to provide solutions that empower businesses to thrive in a competitive market. Their commitment to excellence and customer satisfaction has earned them a strong reputation as a trusted partner for woodworking professionals worldwide.In addition to its exceptional performance, the CNC wood cutting machine is designed for maximum durability and reliability. Its robust construction and high-quality components ensure long-term operation with minimal maintenance requirements, offering woodworkers peace of mind and uninterrupted production capability. The machine is also equipped with advanced safety features to protect operators and maintain a secure working environment.Furthermore, the CNC wood cutting machine is designed for versatility, allowing woodworkers to explore a wide range of creative possibilities. Whether it's producing custom furniture, intricate carvings, or decorative elements, the machine's flexibility enables woodworkers to bring their design concepts to life with precision and efficiency. Its dynamic cutting capabilities and multi-axis control provide endless opportunities for customization and personalization.The company's dedication to providing comprehensive customer support and service further enhances the value of the CNC wood cutting machine. From installation and training to ongoing technical assistance, the company's team of experts is committed to ensuring that woodworkers maximize the potential of their investment. With a global network of service centers and a responsive support system, the company stands behind its products and strives to deliver unparalleled customer satisfaction.In conclusion, the introduction of the latest CNC wood cutting machine by this leading manufacturing company represents a significant advancement in the woodworking industry. Its cutting-edge technology, precision engineering, and versatile capabilities make it a game-changer for woodworkers seeking to elevate their craft and business. With a strong focus on performance, durability, and customer support, the machine sets a new standard for excellence in wood cutting and carving, empowering woodworking professionals to achieve remarkable results and unlock new possibilities.

CNC Programming Book: Tips and Techniques for Metal and Woodworking Machines

CNC Machines for Metal and Wood: Tips and Techniques for ProgrammersCNC machines have become increasingly popular in recent years, especially in the field of metalworking and woodworking. These machines offer precise cutting and engraving capabilities, making them a favorite among manufacturers and artisans alike. However, the intricacies of CNC programming can be overwhelming, especially for those new to the technology. That's where Peter Smid's CNC Tips and Techniques: A Reader for Programmers comes in.This book is the perfect guide for those who want to learn more about CNC programming. Smid's expertise in the field is evident in the way he breaks down complex topics into easy-to-understand sections. Whether you're looking to improve your existing skills or just getting started, this book has something for everyone.One of the standout features of this book is the inclusion of tips and techniques specific to metalworking and woodworking. Smid's extensive experience in both fields makes him uniquely qualified to provide insights and strategies that are tailored to each industry. Whether you're working with hard metals or fragile woods, you'll find tips and tricks to help you achieve precise and accurate results every time.Another great feature of this book is the emphasis on practical applications. Smid doesn't just provide theoretical knowledge - he also includes real-world examples of how CNC programming can be used in manufacturing and artistic contexts. This makes the content more engaging and relevant for readers who are looking to apply their newfound knowledge in practical ways.Of course, one of the biggest benefits of CNC machines is their efficiency. They allow manufacturers to produce large quantities of products quickly and accurately. Smid's book takes this into account, with chapters dedicated to optimizing speed and reducing cycle time. These tips can help manufacturers save time and money, while maintaining high levels of quality and precision.In summary, CNC Tips and Techniques: A Reader for Programmers is an excellent resource for anyone looking to improve their CNC programming skills, particularly in metalworking and woodworking. It offers practical strategies, real-world examples, and expert guidance from an industry veteran. Whether you're an experienced programmer or just starting out, this book is sure to help you achieve better results with your CNC machines. So what are you waiting for? Start reading today!

High Precision Laser Cutter with USB Port & Water Temperature Control System

article about the JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter.JFT has released its latest productivity-enhancing equipment, the JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter. This new machine has been designed to help businesses and individuals cut, engrave and create precise designs with ease.One of the most noteworthy features of the machine is its water temperature control system. This feature regulates the temperature of the laser source to ensure that the device operates at a consistent and high level of efficiency.The laser energy is also adjustable, which is a valuable feature for those who require different settings for various materials and projects. JFT has added this feature to give users more control and precision when working with different materials.The JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter comes with a USB port that allows users to connect the machine directly to their computer. This means that individuals and businesses can easily transfer their designs to the machine without any additional software or programs.Moreover, the laser cutter has a communication interface that uses USB, enabling users to control the device from their computer. This feature enhances the precision of the machine and makes it more user-friendly.The machine is designed to have an engraving area of 30x20cm and the laser power is 60W AC110V/60Hz (or AC220v/50hz). This provides sufficient power to work with a wide range of materials, and perform intricate designs and cuts for different types of projects.Apart from that, the engraving speed is also adjustable from 0-500mm/s, which gives users the flexibility to work with different materials and designs. The high resolution ratio of 0.001mm helps to produce laser-precise designs, and the carving depth of 0-5mm means that it can handle deeper cuts than other laser cutters.The JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter is designed to work with CorelDraw software, a comprehensive graphic design suite that is popular among designers and businesses worldwide. This means that businesses and individuals can easily create and edit their designs using their preferred software and transfer them directly to the machine.To ensure that the machine is always functioning at an optimal level, it uses a pure circulating cooling system. This system aids in removing excess heat, which in turn lengthens the lifespan of the machine.In conclusion, the JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter is an exceptional investment for a wide range of businesses and individuals who need a high-precision laser cutter for their projects. It comes with several valuable features that provide control and flexibility when working with different materials, making it an ideal addition to any design or creative studio.

High-Quality Aluminum CNC Cutting Services for Precision Results

Aluminum CNC Cutting Technology Revolutionizing Manufacturing IndustryWith the rapid advancement of technology, the manufacturing industry has been witnessing significant changes in the way products are fabricated. One such revolutionary technology that has been making waves in the industry is Aluminum CNC Cutting. This cutting-edge technology has proven to be a game-changer, offering precision and efficiency in the production of aluminum parts and components.Utilizing state-of-the-art CNC (Computer Numerical Control) machines, Aluminum CNC Cutting is capable of creating complex and intricate designs with utmost precision. This technology has gained widespread popularity due to its ability to deliver high-quality finished products with minimal human intervention. This ensures not only accuracy but also consistency in the manufacturing process, ultimately leading to cost savings and increased productivity.The company {} is at the forefront of this technological revolution in the manufacturing industry. With their cutting-edge CNC machines and expertise in aluminum fabrication, they have been able to cater to the diverse needs of their customers. With a focus on precision engineering and attention to detail, the company has established itself as a leader in the fabrication of aluminum components using CNC cutting technology.The CNC machines utilized by {} are equipped with advanced software that allows for intricate designs to be translated into reality with precision. This level of accuracy is essential, especially in industries such as aerospace, automotive, and electronics, where even the slightest deviation from specifications can result in significant consequences. With Aluminum CNC Cutting, {} has been able to consistently meet the stringent requirements of these industries, earning a reputation for reliability and quality.One of the key advantages of Aluminum CNC Cutting is its ability to handle a wide range of aluminum grades, from the softer aluminum alloys to the tougher and more heat-resistant ones. This versatility enables {} to cater to a diverse range of industries and applications, providing tailored solutions to meet the specific needs of their customers. Whether it's producing complex components for aerospace applications or intricate parts for consumer electronics, Aluminum CNC Cutting has proven to be a versatile and efficient solution.In addition to precision and versatility, Aluminum CNC Cutting also offers increased efficiency and reduced lead times. With the ability to automate the manufacturing process, {} has been able to significantly reduce production times while ensuring consistent quality. This not only benefits their customers by providing faster turnaround times but also allows {} to take on a larger volume of orders without compromising on quality.Furthermore, Aluminum CNC Cutting has also been instrumental in minimizing material wastage. Traditional manufacturing methods often result in significant material wastage due to the nature of the cutting process. However, with the precision and accuracy offered by CNC machines, {} has been able to optimize material usage, resulting in cost savings for both the company and its customers.As the demand for precision-engineered aluminum components continues to grow, the role of Aluminum CNC Cutting in the manufacturing industry is only set to become more significant. Its ability to offer unparalleled precision, efficiency, and versatility has made it an indispensable technology for companies across various industries.With a commitment to innovation and a focus on delivering exceptional quality, {} is poised to continue leading the way in the application of Aluminum CNC Cutting technology. As they continue to push the boundaries of what is possible with CNC machining, the manufacturing industry can expect to see even greater advancements in the fabrication of aluminum components.

The Ultimate Guide to CNC Machine Wood Carving

Title: Revolutionary CNC Machine Carving Wood Set to Transform the Woodworking IndustryIntroduction:The woodworking industry is about to witness a new era of precision and efficiency with the introduction of an innovative CNC machine for carving wood by a leading company. This advanced technology is set to revolutionize the field, offering unmatched precision, user-friendly operation, and increased productivity. By combining cutting-edge engineering with the latest software and advanced automation, the company is poised to reshape the woodworking landscape. With an emphasis on quality craftsmanship, this CNC machine is poised to enhance the creation of furniture, sculptures, and other intricate wooden designs.Body:1. Evolution of Woodworking Techniques and ToolsOver the centuries, woodworking has evolved from traditional hand tools to the introduction of machinery and automation. The advent of computer numerical control (CNC) technology has significantly transformed the industry, allowing for high-precision and efficient operations. This CNC machine for carving wood represents yet another groundbreaking milestone in the journey of woodworking.2. Unparalleled Precision and EfficiencyThe new CNC machine offers exceptional precision, ensuring intricate designs can be accurately carved into wood. With the ability to work on a variety of wood types, from hardwood to softwood, the machine provides optimum results without compromising quality. Each carved piece benefits from consistent accuracy, eliminating human error and ensuring a flawless final product.3. User-Friendly OperationThe company has designed this CNC machine with the aim of streamlining the woodworking process. Careful consideration has been given to ensure intuitive and user-friendly operation, allowing both experts and beginners to harness its capabilities. The machine's software interface simplifies the production process, enabling users to effortlessly design, program, and execute their creations with a few clicks. This reduces the learning curve typically associated with CNC machines, making it accessible to a wider range of woodworking professionals.4. Enhanced Automation and Time EfficiencyBy automating complex wood carving tasks, this CNC machine significantly reduces production time. Time-consuming manual operations are now seamlessly carried out by the machine, allowing craftsmen to focus on design, finishing touches, and other creative aspects of their projects. With improved productivity, woodworking businesses can undertake larger projects and meet strict deadlines, ultimately boosting profitability.5. Diverse Applications in WoodworkingThe versatility of this CNC machine extends to various applications within the woodworking industry. Whether creating custom furniture pieces, elaborate wooden sculptures, or intricate architectural details, the machine delivers exceptional results. Its adaptability to different wood types and design intricacies ensures a wide range of creative possibilities for artisans.6. Commitment to Quality CraftsmanshipThe company behind this CNC machine underscores its commitment to quality craftsmanship. By digitalizing and automating certain woodworking processes, the machine aims to augment traditional woodworking methods rather than replacing them. The technology empowers artisans to execute their creative visions more accurately, efficiently, and consistently while honoring the integrity of handcrafted woodworking traditions.Conclusion:The woodworking industry is on the brink of a technological leap with the introduction of an advanced CNC machine for carving wood. This groundbreaking innovation promises unparalleled precision, user-friendly operation, and enhanced automation, setting the stage for a new era of woodworking excellence. By integrating cutting-edge technology with the artistry of woodworking, this CNC machine is ready to empower craftsmen, streamline production, and elevate the industry as a whole. Brace yourself for a revolution in woodworking – the future is here.

How to Choose the Best Wooden Router for CNC Machining

Manufacturing industry is undergoing a significant technological revolution in recent years with the introduction of advanced machinery and equipment. One such advanced equipment that has been making waves in the industry is the CNC Wooden Router. This cutting-edge technology has revolutionized the way wooden products are designed and fabricated, providing more precision, efficiency, and versatility in woodworking projects.The CNC Wooden Router, developed by {company name}, is a state-of-the-art machine that is designed to take woodworking to the next level. The machine utilizes computer numerical control (CNC) technology to automate the cutting and carving process, allowing for highly detailed and intricate designs to be created with utmost precision. This advanced woodcarving machine has become the go-to choice for companies and woodworkers looking to streamline their production process and enhance the quality of their finished products.{Company name} is at the forefront of innovation in the manufacturing industry, with a strong focus on developing cutting-edge machinery for various applications. The CNC Wooden Router is a testament to the company's commitment to excellence and its dedication to providing top-of-the-line equipment for its clients. With a team of skilled engineers and technicians, {company name} has been able to create a CNC Wooden Router that exceeds industry standards, setting a new benchmark for woodworking machinery.One of the key advantages of the CNC Wooden Router is its ability to precisely cut and carve wood, enabling intricate designs and patterns to be created with ease. This level of precision is unmatched by traditional woodworking methods, making the CNC Wooden Router an indispensable tool for woodworkers, carpenters, and furniture manufacturers. Moreover, the machine is equipped with advanced software that allows for seamless integration with design programs, enabling users to easily input their custom designs and have them accurately replicated on wood.In addition to its precision, the CNC Wooden Router is also known for its speed and efficiency. The automated cutting and carving process significantly reduces production time, allowing for faster turnaround on woodworking projects. This not only improves overall productivity but also gives manufacturers a competitive edge in the market. With the ability to produce high-quality wood products at a faster rate, businesses can meet customer demands more effectively and take on more projects with confidence.Furthermore, the CNC Wooden Router offers unparalleled versatility, allowing for a wide range of woodworking applications. From crafting fine furniture and cabinetry to creating intricate wooden artworks, the machine can handle various types of wood and produce a myriad of designs. This versatility makes it an ideal choice for businesses looking to diversify their offerings and cater to a broader customer base.The CNC Wooden Router from {company name} also comes with robust built-in safety features to ensure the protection of users and minimize the risk of accidents. With safety being a top priority, the machine is designed to meet industry safety standards, giving operators peace of mind while working with the equipment.Overall, the CNC Wooden Router from {company name} represents a significant leap forward in the woodworking industry. Its precision, efficiency, and versatility make it a valuable asset for businesses looking to elevate their woodworking capabilities and stay ahead of the competition. As the manufacturing industry continues to embrace advanced technology, the CNC Wooden Router is poised to play a pivotal role in shaping the future of woodworking.In conclusion, {company name}'s CNC Wooden Router is a game-changer in the woodworking industry, offering a perfect blend of precision, efficiency, and versatility. With its advanced features and innovative design, the machine is set to revolutionize the way wood products are designed and fabricated. As businesses continue to seek ways to improve productivity and produce high-quality wood products, the CNC Wooden Router is expected to be a sought-after solution for manufacturers and woodworkers alike.

Wood Milling Machine for DIY Projects: An Ultimate Guide

Introducing the latest innovation in woodworking technology - the DIY CNC Wood Milling Machine. This state-of-the-art machine is set to revolutionize the way woodworkers approach their craft, making intricate and precise wood milling easier and more accessible than ever before. With its user-friendly design and advanced features, this CNC wood milling machine is perfect for both professionals and hobbyists looking to take their woodworking projects to the next level.This CNC wood milling machine is equipped with a robust and efficient motor, ensuring smooth and accurate milling operations. Its precise cutting capabilities allow for intricate designs and detailed woodwork, making it ideal for projects such as furniture making, cabinetry, and decorative wood crafts.One of the key features of this DIY CNC Wood Milling Machine is its easy-to-use interface. With its intuitive control panel and user-friendly software, woodworkers can easily program and execute their milling designs with precision and ease. This makes the machine accessible to woodworkers of all skill levels, from beginners to experienced professionals.In addition to its cutting-edge technology, this CNC wood milling machine is also designed with safety in mind. It is equipped with features such as emergency stop buttons and protective enclosures, ensuring that woodworkers can operate the machine with peace of mind.Moreover, this DIY CNC Wood Milling Machine is highly customizable, allowing woodworkers to tailor it to their specific needs. Whether it's adjusting the cutting speed, changing the tooling, or modifying the milling paths, this machine offers a high degree of flexibility and versatility. This makes it an invaluable tool for woodworkers who require a custom approach to their milling projects.The company behind this groundbreaking CNC wood milling machine, {}, is a recognized leader in the woodworking industry. With a strong commitment to innovation and quality, {} has been providing woodworkers with cutting-edge tools and solutions for years. Their dedication to excellence is reflected in the design and performance of this DIY CNC Wood Milling Machine. {} is dedicated to providing woodworkers with the highest quality products and support, making it a brand that woodworkers can trust. With a focus on customer satisfaction and innovation, {} has established itself as a leading authority in the woodworking community."We are thrilled to introduce the DIY CNC Wood Milling Machine to the market," said a spokesperson for {}. "We believe that this machine will empower woodworkers to explore new creative possibilities and take their woodworking projects to new heights. With its advanced technology and user-friendly design, we are confident that this CNC wood milling machine will be a game-changer for the woodworking community."The DIY CNC Wood Milling Machine from {} is set to make a significant impact on the woodworking industry, providing woodworkers with a powerful and versatile tool for precision milling. With its advanced features, user-friendly design, and commitment to quality, this CNC wood milling machine is a must-have for anyone looking to elevate their woodworking projects.

Top 5 Advantages of Fibre Laser Cutting for Precision Metal Cutting

Fibre Laser Cutting Metal: Revolutionizing Industrial Production ProcessesSince its inception, Fibre Laser Cutting Metal technology has revolutionized the industrial production processes, and its use has expanded from the aerospace and automotive industries to a plethora of other industries that require precision and accuracy in cutting different types of metals. In this article, we will delve into what makes Fibre Laser Cutting Metal technology unique and how it has transformed industrial production processes.Fibre Laser Cutting Metal technology is based on the use of a high-power laser beam to melt and vaporize metals. Unlike traditional cutting methods that use physical blades and shears, Fibre Laser Cutting Metal technology offers several advantages, including greater precision, speed, and flexibility. The technology's precision and accuracy are achieved through a combination of advanced software, hardware, and optics that control the laser beam's intensity and focus, resulting in a precise and clean cut. In addition, the technology also allows for greater flexibility in cutting different types of metals and shapes, enabling manufacturers to deliver quality products quickly and efficiently.One of the leading companies in Fibre Laser Cutting Metal technology is {}, a leading manufacturer of a range of laser cutting machines. The company's products are used in various sectors, including aerospace, automotive, construction, and medical industries, to perform a range of precision cutting tasks. With over three decades of experience in the laser industry, the company continues to innovate its products, offering cutting-edge solutions to meet the evolving needs of its clients.A key advantage of {}'s Fibre Laser Cutting Metal technology is its high-level of automation, which reduces labor costs, increase production rates, and eliminates human errors. The machines are equipped with advanced software that controls a range of parameters, including cutting speed, power, and focus, ensuring quality and consistency across all production runs. In addition, the machines are easy to operate, a feature that makes them ideal for busy industrial production environments.The Fibre Laser Cutting Metal technology offered by {} is also energy-efficient, an attribute that makes it environmentally friendly and cost-effective. The laser technology requires less energy to perform cutting tasks compared to traditional methods, resulting in significant energy savings for industrial companies.Furthermore, {}'s Fibre Laser Cutting Metal technology offers a range of customization options, allowing manufacturers to tailor the cutting machines to their respective production needs. The company offers a range of machines with different power and speed capabilities, ensuring that its clients have access to products that cater to their specific requirements.In conclusion, Fibre Laser Cutting Metal technology has transformed industrial production processes, and {company name} has played a significant role in the technology's development, manufacturing, and distribution. The technology's precision, flexibility, energy efficiency, and automation have made it a benchmark technology in the manufacturing industry, powering the production of a range of products that meet the highest quality standards. As technology continues to advance, {} remains committed to delivering cutting-edge solutions that enable its clients to optimize their production processes and remain competitive in their respective industries.

Top CNC Wood Router Machine Manufacturers and Suppliers in China - Visit Our Factory for Long-Term Cooperation Opportunities

CNC Wood Router Machines: The Next Leap in Woodwork ManufacturingIn the world of woodworking, there's a constant need for innovation that can streamline production processes, enhance productivity, and ultimately improve the quality of the final product. The advent of Computer Numerical Control (CNC) technology has proven to be a game-changer in this industry, revolutionizing how woodworking is done.CNC wood router machines have become increasingly popular in recent years, as they offer unparalleled precision, speed, and consistency. If you're not familiar with this technology, let's take a closer look at what it is, how it works, and why it's quickly becoming a must-have tool for woodworkers.What is a CNC Wood Router Machine?At its core, a CNC wood router machine is a computer-controlled cutting tool that's primarily used for shaping wood. The technology involves the use of sophisticated software that converts a 2D or 3D design into machine-readable code, which is then fed into the router's computer. This allows the machine to make highly accurate cuts, curves, and patterns that would be virtually impossible to achieve by hand.CNC Router Machine Design: How It WorksCNC router machines are designed to cut wood, plastic, or metal using a cutting tool that's mounted onto a spindle. The spindle rotates the cutting tool at high speeds, while the machine's computer-controlled X, Y, and Z-axis motors determine the cutting path. In other words, the machine moves the cutting tool along the pre-determined path, according to the design specifications.One key advantage of CNC router machines is that they can be programmed to make highly precise cuts, regardless of the complexity of the design. This means that the same design can be replicated on different pieces of wood with extraordinary accuracy and consistency.Benefits of Using CNC Wood Router MachinesSo, why are more and more woodworkers turning to CNC routers? Here are some of the key benefits.1. Precision - CNC wood router machines can make precise cuts and shapes, which results in high-quality products.2. Ease of use - The software used to program the machine is user-friendly and intuitive, which means that even beginners can use the machine safely and effectively.3. Efficiency - CNC router machines can work for extended periods without interruption, which means that large batches of woodwork can be produced quickly and efficiently.4. Versatility - CNC router machines can work on a variety of wood types, including hard and softwood, MDF, and plywood.5. Cost-Effective - The use of CNC wood router machines can reduce labor costs, and they can produce the same quality of work as manual labor would.ConclusionCNC wood router machines represent the next step in woodworking technology. They offer unmatched precision, speed, and efficiency, making them an excellent investment for woodworkers and manufacturers alike. If you're looking to improve your woodworking processes and enhance the quality of your final products, then it's time to consider investing in a CNC wood router machine. The market offers various options with different features, so it's best to research before making a final decision.

Advanced CNC Machine for Metal and Wood: A Game-Changer in Precision Fabrication

A leading CNC machinery company is revolutionizing the manufacturing industry with its innovative CNC machine for metal and wood. This cutting-edge technology has the capability to greatly enhance productivity and precision in a wide range of manufacturing processes.The CNC machine is equipped with state-of-the-art technology that allows for the precise cutting, shaping, and carving of both metal and wood materials. This advanced machinery is ideal for a variety of industries, including aerospace, automotive, furniture, and more. With its ability to work with both metal and wood, this CNC machine offers unmatched versatility for manufacturers looking to streamline their production processes.One of the key features of this new CNC machine is its high level of automation, which allows for seamless operation and minimal human intervention. This not only improves efficiency but also reduces the risk of errors, resulting in higher quality products. Additionally, the machine is designed to be user-friendly, with intuitive controls and software that make it easy for operators to program and operate.In addition to its impressive performance capabilities, this CNC machine is also designed with durability and reliability in mind. The company has a reputation for producing high-quality machinery that is built to withstand the demands of industrial settings. This means that manufacturers can rely on this CNC machine to deliver consistent, precise results day in and day out.Furthermore, the company offers comprehensive technical support and training to ensure that customers can make the most of their investment in this CNC machine. This includes on-site assistance with installation and setup, as well as ongoing support to address any technical issues or questions that may arise.The introduction of this advanced CNC machine is expected to have a significant impact on the manufacturing industry. With its ability to handle both metal and wood materials with precision and efficiency, this machinery has the potential to revolutionize production processes across a wide range of industries.In addition to the tangible benefits of improved productivity and quality, this CNC machine also offers manufacturers the opportunity to explore new design possibilities and expand their capabilities. The ability to work with both metal and wood opens up new opportunities for innovation and creativity, allowing manufacturers to explore new product designs and production techniques.Overall, this CNC machine is poised to make a significant impact on the manufacturing industry. Its advanced technology, combined with the company's commitment to quality and support, sets a new standard for CNC machinery. With its potential to improve efficiency, precision, and versatility, this CNC machine is a game-changer for manufacturers looking to stay ahead in a competitive marketplace.