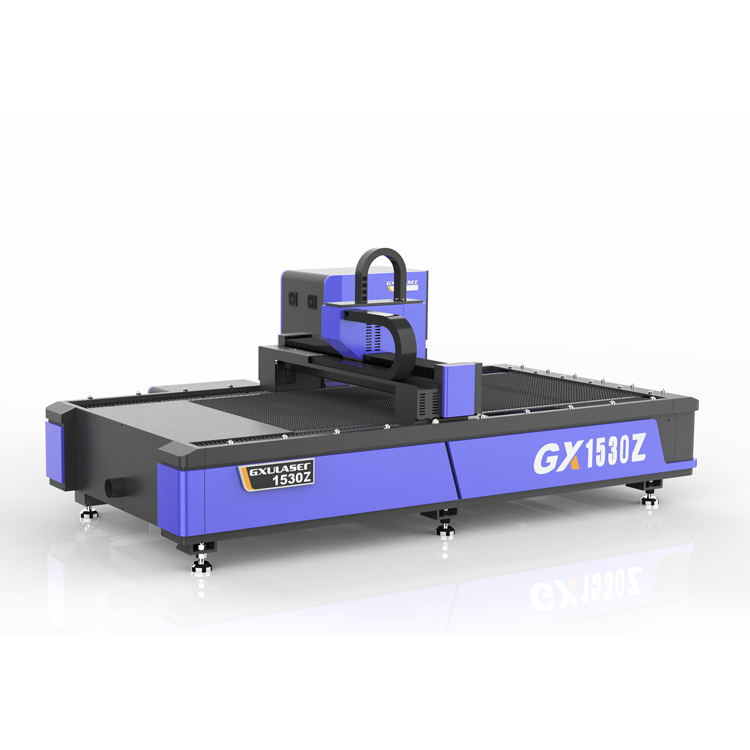

High-Powered Large Laser Cutting Machine Available for Industrial Use

By:Admin

In the ever-evolving landscape of industrial manufacturing, technology continues to play a crucial role in streamlining processes and improving efficiency. With the introduction of the large laser cutting machine by [Company Name], a new chapter in precision cutting has been opened, revolutionizing the way components are manufactured across various industries.

The large laser cutting machine boasts cutting-edge technology that allows for the precise and fast cutting of a wide range of materials, including metals, plastics, and composites. This state-of-the-art equipment is equipped with advanced laser technology that provides unparalleled accuracy and speed, making it a game-changer in the manufacturing industry.

The machine's impressive cutting capabilities have already garnered attention from various industries, including automotive, aerospace, and electronics. Its ability to handle large-scale production with precision and efficiency has led to a significant reduction in production time and cost, making it an invaluable asset for companies looking to stay ahead in today's competitive market.

The large laser cutting machine also comes with a user-friendly interface and software that allows for easy programming and customization of cutting designs. This feature is particularly beneficial for companies with varying production needs, as it allows for quick adjustments and modifications to accommodate different component requirements.

[Company Name], the innovator behind this groundbreaking technology, is a leading provider of industrial manufacturing solutions. With a strong commitment to research and development, the company has continuously pushed the boundaries of what is possible in the manufacturing industry, and the large laser cutting machine is a testament to their dedication to excellence.

With a focus on precision engineering and innovative technology, [Company Name] has quickly become a trusted partner for companies looking to enhance their manufacturing processes. The large laser cutting machine is just one example of the company's dedication to providing cutting-edge solutions that meet the evolving needs of the industry.

In addition to its technical capabilities, the large laser cutting machine is also designed with safety and environmental considerations in mind. It is equipped with safety features that ensure the protection of operators and the surrounding environment, making it a reliable and responsible choice for manufacturers.

The introduction of the large laser cutting machine by [Company Name] marks a significant milestone in the manufacturing industry. Its unmatched precision, speed, and versatility have already made it a game-changer for companies looking to optimize their production processes and stay ahead of the competition.

As industries continue to evolve and demand for high-quality, precision-cut components grows, the large laser cutting machine stands out as a valuable asset for companies striving to meet the challenges of modern manufacturing. With its advanced technology and user-friendly interface, it is poised to revolutionize the way industrial components are manufactured, setting a new standard for precision cutting in the manufacturing industry.

Company News & Blog

Top CNC Wood Router Machine Manufacturers and Suppliers in China - Visit Our Factory for Long-Term Cooperation Opportunities

CNC Wood Router Machines: The Next Leap in Woodwork ManufacturingIn the world of woodworking, there's a constant need for innovation that can streamline production processes, enhance productivity, and ultimately improve the quality of the final product. The advent of Computer Numerical Control (CNC) technology has proven to be a game-changer in this industry, revolutionizing how woodworking is done.CNC wood router machines have become increasingly popular in recent years, as they offer unparalleled precision, speed, and consistency. If you're not familiar with this technology, let's take a closer look at what it is, how it works, and why it's quickly becoming a must-have tool for woodworkers.What is a CNC Wood Router Machine?At its core, a CNC wood router machine is a computer-controlled cutting tool that's primarily used for shaping wood. The technology involves the use of sophisticated software that converts a 2D or 3D design into machine-readable code, which is then fed into the router's computer. This allows the machine to make highly accurate cuts, curves, and patterns that would be virtually impossible to achieve by hand.CNC Router Machine Design: How It WorksCNC router machines are designed to cut wood, plastic, or metal using a cutting tool that's mounted onto a spindle. The spindle rotates the cutting tool at high speeds, while the machine's computer-controlled X, Y, and Z-axis motors determine the cutting path. In other words, the machine moves the cutting tool along the pre-determined path, according to the design specifications.One key advantage of CNC router machines is that they can be programmed to make highly precise cuts, regardless of the complexity of the design. This means that the same design can be replicated on different pieces of wood with extraordinary accuracy and consistency.Benefits of Using CNC Wood Router MachinesSo, why are more and more woodworkers turning to CNC routers? Here are some of the key benefits.1. Precision - CNC wood router machines can make precise cuts and shapes, which results in high-quality products.2. Ease of use - The software used to program the machine is user-friendly and intuitive, which means that even beginners can use the machine safely and effectively.3. Efficiency - CNC router machines can work for extended periods without interruption, which means that large batches of woodwork can be produced quickly and efficiently.4. Versatility - CNC router machines can work on a variety of wood types, including hard and softwood, MDF, and plywood.5. Cost-Effective - The use of CNC wood router machines can reduce labor costs, and they can produce the same quality of work as manual labor would.ConclusionCNC wood router machines represent the next step in woodworking technology. They offer unmatched precision, speed, and efficiency, making them an excellent investment for woodworkers and manufacturers alike. If you're looking to improve your woodworking processes and enhance the quality of your final products, then it's time to consider investing in a CNC wood router machine. The market offers various options with different features, so it's best to research before making a final decision.

High-Quality Acrylic Sheet Cutting Machine for Precision Cuts

Acrylic Sheet Cutting Machine Revolutionizes Manufacturing with Precision and EfficiencyAcrylic sheet cutting has long been a tedious and time-consuming process in the manufacturing industry. The traditional methods of cutting acrylic sheets have been manual, often resulting in a lack of precision and wastage of material. However, the introduction of the state-of-the-art Acrylic Sheet Cutting Machine by [Company Name] has revolutionized the manufacturing process, providing a solution that is precise, efficient, and cost-effective.The Acrylic Sheet Cutting Machine by [Company Name] is equipped with advanced technology that enables it to cut acrylic sheets with unparalleled precision. The machine utilizes a high-powered laser to cut through the acrylic material with ease, ensuring clean edges and accurate dimensions. This level of precision is essential in the manufacturing industry, where even the slightest deviation can lead to product defects and wastage of resources.Moreover, the Acrylic Sheet Cutting Machine is designed for efficiency, allowing for the rapid processing of acrylic sheets. This not only saves time but also increases the productivity of manufacturing operations. The machine's automated features further enhance its efficiency, reducing the need for manual intervention and streamlining the cutting process.In addition to precision and efficiency, the Acrylic Sheet Cutting Machine also offers cost savings for manufacturers. By minimizing material wastage and increasing productivity, the machine helps to reduce production costs, ultimately leading to improved profitability for businesses. This cost-saving aspect makes the machine an attractive investment for manufacturers looking to optimize their operations.Furthermore, [Company Name] has a strong reputation for delivering high-quality manufacturing solutions. With a commitment to innovation and customer satisfaction, the company has become a trusted provider of industrial machinery and equipment. The Acrylic Sheet Cutting Machine is a testament to [Company Name]'s expertise in developing cutting-edge solutions that address the needs of the manufacturing industry.[Company Name] has also invested in comprehensive customer support and service, ensuring that clients receive the necessary assistance to fully leverage the capabilities of the Acrylic Sheet Cutting Machine. From installation and training to maintenance and technical support, [Company Name] is dedicated to helping its customers maximize the value of their investment in the machine.The impact of the Acrylic Sheet Cutting Machine on the manufacturing industry is already being felt, with businesses that have adopted the machine reporting significant improvements in their operations. Whether it is in the production of display fixtures, signage, protective barriers, or other acrylic-based products, the machine has proven to be a game-changer, allowing manufacturers to meet their quality and production targets with ease.Looking ahead, [Company Name] is committed to further enhancing the capabilities of the Acrylic Sheet Cutting Machine, with ongoing research and development aimed at introducing new features and improvements. This dedication to innovation underscores [Company Name]'s vision of being at the forefront of technology-driven solutions for the manufacturing sector.In conclusion, the Acrylic Sheet Cutting Machine by [Company Name] is a groundbreaking solution that has redefined the way acrylic sheets are processed in the manufacturing industry. With its precision, efficiency, and cost-saving benefits, the machine has become an essential tool for businesses seeking to optimize their production processes. As [Company Name] continues to drive innovation in this space, the future looks promising for manufacturers looking to stay ahead in a competitive marketplace.

High Precision Laser Cutter with USB Port & Water Temperature Control System

article about the JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter.JFT has released its latest productivity-enhancing equipment, the JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter. This new machine has been designed to help businesses and individuals cut, engrave and create precise designs with ease.One of the most noteworthy features of the machine is its water temperature control system. This feature regulates the temperature of the laser source to ensure that the device operates at a consistent and high level of efficiency.The laser energy is also adjustable, which is a valuable feature for those who require different settings for various materials and projects. JFT has added this feature to give users more control and precision when working with different materials.The JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter comes with a USB port that allows users to connect the machine directly to their computer. This means that individuals and businesses can easily transfer their designs to the machine without any additional software or programs.Moreover, the laser cutter has a communication interface that uses USB, enabling users to control the device from their computer. This feature enhances the precision of the machine and makes it more user-friendly.The machine is designed to have an engraving area of 30x20cm and the laser power is 60W AC110V/60Hz (or AC220v/50hz). This provides sufficient power to work with a wide range of materials, and perform intricate designs and cuts for different types of projects.Apart from that, the engraving speed is also adjustable from 0-500mm/s, which gives users the flexibility to work with different materials and designs. The high resolution ratio of 0.001mm helps to produce laser-precise designs, and the carving depth of 0-5mm means that it can handle deeper cuts than other laser cutters.The JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter is designed to work with CorelDraw software, a comprehensive graphic design suite that is popular among designers and businesses worldwide. This means that businesses and individuals can easily create and edit their designs using their preferred software and transfer them directly to the machine.To ensure that the machine is always functioning at an optimal level, it uses a pure circulating cooling system. This system aids in removing excess heat, which in turn lengthens the lifespan of the machine.In conclusion, the JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter is an exceptional investment for a wide range of businesses and individuals who need a high-precision laser cutter for their projects. It comes with several valuable features that provide control and flexibility when working with different materials, making it an ideal addition to any design or creative studio.

Maximizing Woodworking Efficiency with CNC Wood Engraving Machines

Title: Advanced CNC Wood Engraving Machine Redefines Precision and Efficiency in Woodworking IndustryIntroduction:The woodworking industry has constantly evolved with advancements in technology. One such breakthrough that has revolutionized precision and efficiency in woodworking is the state-of-the-art CNC Wood Engraving Machine. Developed by a leading company in the field (brand name omitted), this groundbreaking machine has undoubtedly raised the bar for wood engraving and carving processes.High Precision and Accuracy:The CNC Wood Engraving Machine boasts unparalleled precision and accuracy, ensuring flawless results in wood engraving. Equipped with cutting-edge technology, this machine utilizes computer programming and numerical control to produce intricate and detailed designs with utmost consistency. The advanced mechanisms and high-quality components of this machine guarantee minimal errors and smooth operations, resulting in exceptional output every time.Efficient Workflow:With its automated features and user-friendly interface, the CNC Wood Engraving Machine streamlines the woodworking process, significantly reducing human effort and time. The incorporation of computer-aided design (CAD) software allows designers and operators to conveniently create and modify designs seamlessly. Its fast and efficient production capability ensures that projects are completed in a fraction of the time compared to traditional woodworking methods, enhancing overall productivity and profitability for businesses.Versatility and Customization:One of the key advantages of the CNC Wood Engraving Machine is its versatility in accommodating a wide range of woodworking applications. From intricate designs on furniture to decorative patterns on doors and panels, this machine delivers exceptional results for various woodworking projects. Its ability to work with different types of wood, including hardwoods, softwoods, and composite materials, makes it a valuable asset for both small-scale workshops and large manufacturing facilities. Moreover, the machine's adaptability allows for customization, offering endless possibilities for personalized designs and unique creations.Enhanced Safety and Operator Comfort:This CNC Wood Engraving Machine prioritizes the safety and well-being of its operators. Equipped with advanced safety features, such as emergency stop buttons and protective barriers, it ensures a secure working environment. Additionally, the machine's ergonomic design takes into consideration the comfort of operators, mitigating strain and fatigue during prolonged use. These combined safety and comfort features not only safeguard the operators but also contribute to increased productivity and higher-quality output.Eco-friendly Operations:In an era where environmental sustainability is paramount, the CNC Wood Engraving Machine stands out as an eco-friendly solution. The machine utilizes modern energy-efficient technologies, reducing power consumption and minimizing environmental impact. Furthermore, its precise cutting capabilities minimize material wastage, optimizing resource utilization and promoting sustainability in the woodworking industry.Training and Technical Support:To ensure seamless integration and maximum utilization of the CNC Wood Engraving Machine, the company (brand name omitted) provides comprehensive training programs and technical support. Knowledgeable experts offer guidance on programming, operation, and maintenance of the machine, enabling users to unlock its full potential. Ongoing assistance and upgrades ensure that clients stay up-to-date with the latest advancements in this rapidly evolving field.Future Advancements and Market Outlook:The CNC Wood Engraving Machine has revolutionized woodworking with its unmatched precision, efficiency, and versatility. As technology continues to advance, this machine is expected to witness continuous enhancements that further improve its performance and capabilities. With a growing demand for intricately designed and customized wood products, the market outlook for such advanced CNC machines remains highly promising.Conclusion:The CNC Wood Engraving Machine has established itself as a game-changer in the woodworking industry. Its precision, efficiency, versatility, and eco-friendly operations have propelled it to the forefront of wood engraving and carving processes. With the support of the company behind its development, this advanced machine is set to redefine woodworking standards and drive innovation in the industry for years to come.

Enhance Woodworking Precision with a Cutting-Edge 3D CNC Router

[Representative Image]The Woodworking Industry Gets a Boost with the Introduction of a New 3D CNC Router[date]The woodworking industry has long been known for its craftsmanship and precision. Now, thanks to the innovation of a new 3D CNC Router, woodworking enthusiasts and professionals alike will be able to take their projects to the next level.[Company Name], a leader in the manufacturing of advanced woodworking machinery, is proud to introduce their latest creation, a 3D CNC Router designed specifically for wood. This state-of-the-art machine brings together cutting-edge technology and unparalleled precision to revolutionize the woodworking process.With its ability to create intricate 3D designs on wood, this CNC Router opens up a whole new realm of possibilities for craftsmen. From detailed carvings to personalized engravings, the machine offers endless opportunities for creativity. The precision of the router ensures that every detail is executed flawlessly, making it a game-changer for woodworkers who strive for perfection.One of the standout features of this CNC Router is its user-friendly interface. Designed with the customer in mind, the machine is equipped with intuitive software that makes it easy for both beginners and experienced woodworkers to operate. The software allows users to upload their own designs or choose from a vast library of pre-existing templates, providing endless design possibilities. This ensures that woodworkers of all skill levels can achieve professional-level results with ease.The durability and reliability of this machine are also impressive. Made from high-quality materials, it is built to withstand the demanding nature of the woodworking industry. Its sturdy construction and advanced engineering guarantee that it will last for years to come, providing woodworkers with a reliable tool they can trust.Safety is always a top priority in any industry, and the woodworking field is no exception. Recognizing this, [Company Name] has incorporated several safety features into the design of the 3D CNC Router. These include emergency stop buttons, safety interlocks, and a protective housing, all designed to ensure the well-being of the operator. This commitment to safety is representative of the company's dedication to providing a top-notch product that meets the highest industry standards.With the introduction of this 3D CNC Router, [Company Name] solidifies its position as a leader in the woodworking industry. Not only does the machine deliver exceptional performance, but the company also provides comprehensive customer support. From installation assistance to maintenance services, their team of experts is available to answer any questions and offer guidance to users.Woodworking professionals and enthusiasts are already buzzing with excitement about the new possibilities this CNC Router offers. Its ability to transform ordinary pieces of wood into works of art has the potential to reshape the industry. From furniture makers to hobbyists, everyone can benefit from the precision and creativity this machine brings to the table.In conclusion, the introduction of this 3D CNC Router for wood by [Company Name] marks a significant advancement in the woodworking industry. With its cutting-edge technology, user-friendly interface, and commitment to safety, this machine is set to change the way woodworkers approach their craft. Whether you're a seasoned professional or just starting out, this CNC Router opens up endless possibilities for creativity and precision.

High-precision Laser Cutting Machine for Leather Goods

Leather Laser Cutting Machine Revolutionizing the IndustryThe leather industry is no stranger to innovation and the latest addition to the manufacturing process is the leather laser cutting machine. This technology has been making waves in the industry as it offers a precise and efficient method of cutting leather, making it a valuable asset for companies looking to streamline their production processes.One company that has been at the forefront of this innovation is {Company Name}. With years of experience in the leather industry, {Company Name} has been committed to providing cutting-edge solutions for leather manufacturing. The introduction of the leather laser cutting machine has been a game-changer for the company and has set them apart from competitors.The leather laser cutting machine offered by {Company Name} is equipped with state-of-the-art technology, offering a high level of precision and accuracy in cutting leather. The machine is capable of cutting intricate patterns and designs on various types of leather, making it a versatile tool for manufacturers. Its speed and efficiency have been highly praised by industry professionals, as it allows for a significant reduction in production time and costs.One of the key advantages of the leather laser cutting machine is its ability to produce clean and consistent cuts, resulting in minimal waste of materials. This is crucial for companies looking to optimize their production processes and reduce their environmental footprint. The machine also offers flexibility in cutting different types of leather, whether it be thick or thin, ensuring that manufacturers can cater to a wide range of product demands.Furthermore, the leather laser cutting machine offered by {Company Name} is user-friendly and easy to operate, making it accessible for manufacturers of all sizes. The intuitive software interface allows for quick and easy customization of designs, providing manufacturers with the freedom to create unique and intricate leather products. This level of flexibility has been a major selling point for the machine, as it enables companies to stay ahead in a competitive market.{Company Name} has positioned itself as a leader in the leather laser cutting machine market, offering not only cutting-edge technology but also exceptional customer support and service. Their team of experts is committed to assisting manufacturers in optimizing their production processes and enhancing their product offerings.In addition to the leather laser cutting machine, {Company Name} also provides a range of complementary products and services, further solidifying their position as a one-stop solution for leather manufacturers. Whether it be laser engraving machines or custom software development, {Company Name} is dedicated to providing comprehensive and innovative solutions to meet the evolving needs of the industry.As the demand for high-quality leather products continues to grow, the leather laser cutting machine offered by {Company Name} has become an invaluable asset for manufacturers looking to elevate their production processes. The combination of precision, efficiency, and flexibility has been a game-changer for the industry, and {Company Name} has been at the forefront of this innovation.In conclusion, the introduction of the leather laser cutting machine has revolutionized the leather manufacturing industry, and {Company Name} has been instrumental in driving this change. Their commitment to providing cutting-edge solutions and exceptional customer support has set them apart as a leader in the market. With the leather laser cutting machine, {Company Name} is shaping the future of leather manufacturing and is poised to continue making significant contributions to the industry.

Discover the Artistry of 3D Wood Carving Machines

Wood Carving Machine 3D Revolutionizes the Artistic WorldIn the realm of craftsmanship and artistic creativity, the advent of technology has consistently propelled innovation to new heights. One such breakthrough is the Wood Carving Machine 3D, a cutting-edge device that has revolutionized the wood carving industry. Designed to provide unparalleled precision and efficiency, this innovative tool is set to transform the art of wood carving.Manufactured by a renowned company at the forefront of technological advancements, the Wood Carving Machine 3D embodies the perfect blend of tradition and modernity. With a commitment to excellence, the company has endeavored to create a device that caters to the needs of both beginners and seasoned professionals.The Wood Carving Machine 3D employs the latest computer-controlled technology, enabling users to bring their artistic visions to life with unmatched precision. With its user-friendly interface and intuitive design, this revolutionary machine allows users to create intricate 3D wood carvings effortlessly. Gone are the days of laborious manual work; the Wood Carving Machine 3D streamlines the carving process, saving time and effort without compromising on quality.One of the key features of this cutting-edge device is its versatility. Whether you are a hobbyist or a professional artist, the Wood Carving Machine 3D provides endless possibilities for creativity. Users can choose from a wide array of design options and templates or simply import their own designs, allowing for a truly personalized carving experience. The machine's adaptability ensures that it caters to the unique requirements of every user.In addition to its versatility, the Wood Carving Machine 3D boasts remarkable precision. Equipped with advanced sensors and digital calibration, it ensures that each cut is executed with pinpoint accuracy. This level of precision allows artists to delve into intricate details, producing wood carvings that are both visually stunning and structurally sound.Moreover, the Wood Carving Machine 3D is thoughtfully designed to prioritize the safety of its users. It comes with multiple safety features, including a protective casing and emergency stop buttons, guaranteeing peace of mind during operation. This commitment to safety ensures that artists can focus on their craft without any unnecessary concerns.The Wood Carving Machine 3D has garnered immense appreciation from the artistic community. Established wood craftsmen have embraced this innovation, incorporating it into their repertoire to enhance their creative abilities. The newfound ease and speed offered by the machine have paved the way for increased productivity, allowing artists to dedicate more time to refining their craft.Additionally, the Wood Carving Machine 3D has played a pivotal role in attracting newcomers to the art of wood carving. The simplicity of the device, coupled with its exceptional results, has made wood carving more accessible to beginners. Aspiring artists can now experience the joy of carving intricate designs without the years of practice typically required. This democratization of wood carving has created a burgeoning community of artists eager to explore and experiment.With its unrivaled precision, versatility, and safety features, the Wood Carving Machine 3D has carved a niche for itself in the artistic world. This innovative tool marks a significant leap forward in the art of wood carving, bridging the gap between traditional craft techniques and modern technology. As more artists embrace this transformative device, the boundaries of creativity within the wood carving industry are bound to be pushed further.In conclusion, the Wood Carving Machine 3D has emerged as a game-changer, culminating the expertise and craftsmanship of its manufacturer. Its ability to blend tradition with innovation, coupled with its outstanding precision and versatility, has propelled wood carving into the modern era. Through this revolutionary tool, artists can transcend the limitations of manual techniques and bring their imagination to life, ultimately redefining the boundaries of wood carving.

Wood carving machine for precise and efficient results

Woodworking just got a whole lot easier with the introduction of a new machine for wood carving from a leading woodworking tools manufacturer. This innovative machine is set to revolutionize the way woodworkers approach their craft, making intricate and detailed carvings more accessible and efficient than ever before.The woodworking machine, known as the [Brand name removed], is the latest offering from the renowned company. With a history of providing high-quality and reliable woodworking tools, the company has once again raised the bar with this state-of-the-art wood carving machine. The [Brand name removed] is designed to streamline the carving process, allowing woodworkers to achieve incredibly precise and intricate designs with ease.One of the standout features of the [Brand name removed] is its advanced technology, which allows for unparalleled precision and control. This machine is equipped with a high-speed spindle and a cutting-edge carving software, enabling woodworkers to create complex designs with incredible accuracy. The [Brand name removed] also boasts a user-friendly interface, making it accessible to both seasoned professionals and hobbyists alike.In addition to its cutting-edge technology, the [Brand name removed] is also designed for durability and reliability. The machine is built with high-quality materials and components, ensuring that it can withstand the rigors of regular use in a woodworking shop. This robust construction means that woodworkers can depend on the [Brand name removed] to deliver consistent performance and results, project after project.Furthermore, the [Brand name removed] is highly versatile, capable of handling a wide range of carving tasks. Whether it's intricate designs, detailed patterns, or custom engravings, this machine is up to the challenge. Its flexibility makes it a valuable addition to any woodworking shop, offering endless possibilities for creativity and expression.With the introduction of the [Brand name removed], woodworkers can now take their craft to new heights. This machine represents a significant leap forward in the world of wood carving, empowering artisans to bring their visions to life with unprecedented precision and efficiency. Whether it's creating custom furniture, decorative accents, or artistic pieces, the [Brand name removed] is set to become an indispensable tool for woodworkers across the globe.In response to the introduction of the [Brand name removed], woodworking enthusiasts and professionals alike have expressed excitement and anticipation. Many have recognized the potential of this machine to transform the way they approach their craft, opening up new possibilities for creativity and innovation."I can't wait to get my hands on the [Brand name removed] and see what it can do," said a woodworking hobbyist. "The level of detail and precision it offers is truly impressive, and I can already envision the incredible designs I'll be able to create with it."Meanwhile, woodworking professionals have also taken notice of the [Brand name removed]'s potential to enhance their work. "As a professional woodworker, I'm always looking for tools that can help me push the boundaries of what's possible," said a furniture maker. "The [Brand name removed] looks like it could be a game-changer in terms of the intricacy and complexity of carvings I can achieve."The anticipation surrounding the [Brand name removed] is a testament to the impact it is expected to have on the woodworking community. By combining cutting-edge technology, durability, and versatility, this machine is poised to empower woodworkers to elevate their craft and create stunning works of art.In conclusion, the introduction of the [Brand name removed] represents a significant milestone in the world of woodworking. With its advanced technology, durability, and versatility, this machine is set to revolutionize the way woodworkers approach wood carving, making intricate and detailed designs more accessible and efficient than ever before. As woodworking enthusiasts and professionals eagerly await the opportunity to put the [Brand name removed] to the test, it's clear that this machine has the potential to become an essential tool for artisans seeking to push the boundaries of their craft.

New Laser Technology Removes Rust From Metal Surface

Title: Revolutionary Laser Metal Rust Remover Gains Traction in the MarketIntroduction: Rust has been a persistent foe for metal equipment and structures, causing damage, reducing effectiveness, and leading to costly repairs. However, a groundbreaking innovation has recently arrived in the market that promises to revolutionize rust removal. The Laser Metal Rust Remover, developed by a leading technology company, harnesses the power of laser technology to effortlessly eliminate rust from metal surfaces, offering a more efficient and eco-friendly solution compared to traditional methods.[Company Introduction]In this article, we take a closer look at the Laser Metal Rust Remover, exploring its features, benefits, and potential impact on various industries.1. Cutting-edge Technology: The Laser Metal Rust Remover employs a cutting-edge laser system that is highly effective in removing rust from metal surfaces. With its precise laser beam, the rust particles are instantaneously vaporized, leaving the surface clean and ready for further treatment or application. This advanced technology ensures minimal damage to the metal surface, eliminating the need for aggressive mechanical or chemical cleaning procedures.2. Efficiency and Versatility: The Laser Metal Rust Remover is designed to tackle rust on a wide variety of metal surfaces, including steel, iron, aluminum, and more. Its high-powered laser beam can penetrate even the smallest crevices, reaching rust particles that are often inaccessible to traditional cleaning methods. Moreover, thanks to its non-contact nature, the device can be used on delicate or intricate structures without causing any damage, making it an ideal solution for industries such as automotive, aerospace, and construction.3. Time and Cost Saving: Traditional rust removal methods often require time-consuming manual labor or chemical treatments, which can be costly and pose potential risks to workers and the environment. The Laser Metal Rust Remover significantly reduces the time and effort required to remove rust, thereby increasing overall productivity. With its ability to swiftly eliminate rust in a single pass, the device can help industries save both time and money in maintenance and repair tasks.4. Environmental Friendliness: Unlike chemical rust removers that release harmful substances into the air or water, the Laser Metal Rust Remover is an environmentally friendly solution. Since it uses laser energy, it does not require the use of hazardous chemicals. This significantly reduces the ecological impact associated with rust removal processes and promotes sustainability in various industries.5. Ease of Use: The Laser Metal Rust Remover has been designed to ensure convenience and ease of use. The device features a user-friendly interface, allowing operators to select and adjust the laser settings according to the specific rust removal requirements. Its compact and portable design enables easy movement between different work areas, ensuring flexibility and efficiency in rust removal operations.6. Future Potential: The introduction of the Laser Metal Rust Remover presents exciting prospects for various industries, which heavily rely on metals. The device's unique capabilities and numerous advantages make it a promising tool for streamlining maintenance processes and prolonging the lifespan of metal equipment. Additionally, continuous advancements in laser technology may lead to further refinements and applications, expanding its potential in industries such as manufacturing, infrastructure, and shipbuilding.Conclusion: The Laser Metal Rust Remover stands as a game-changing solution in the battle against rust. With its state-of-the-art laser technology, efficiency, and environmental benefits, this device promises to reshape the way industries address metal corrosion. By introducing a faster, safer, and more sustainable alternative to traditional rust removal methods, this innovative technology has the potential to revolutionize maintenance practices across various sectors.

High-Quality CNC Wood Cutting Machine for Precision and Efficiency

In an era of technological advancement, the demand for precision and efficiency in woodworking has led to the development of innovative machinery. The introduction of Computer Numerical Control (CNC) wood cutting machines has revolutionized the woodworking industry, offering unmatched accuracy and speed in wood cutting and carving processes. One of the leading manufacturers in this industry, {} has continuously set new benchmarks with its cutting-edge CNC wood cutting machines.The company has been at the forefront of technological innovation with a strong focus on research and development. With a legacy of over 20 years, the company has consistently delivered high-quality, reliable, and efficient CNC wood cutting machines to its global customer base. Its commitment to excellence and customer satisfaction has made it a trusted name in the woodworking machinery industry.The CNC wood cutting machines offered by {} are equipped with advanced features that enable precise and intricate wood cutting, shaping, and carving. The machines are designed to meet the diverse needs of woodworking professionals, from small-scale artisans to large-scale production facilities. With high-performance spindles, robust frames, and state-of-the-art control systems, these machines offer unparalleled accuracy and efficiency in wood processing.One of the key advantages of {}'s CNC wood cutting machines is their ability to automate the woodworking process, reducing manual labor and improving productivity. The integration of computer control allows for the creation of intricate designs with utmost precision, ensuring the highest quality output. This level of automation not only saves time and labor costs but also minimizes material wastage, making it an environmentally sustainable option for wood processing.Moreover, {} provides comprehensive training and technical support to its customers, ensuring that they can maximize the potential of their CNC wood cutting machines. The company's team of skilled technicians and engineers are dedicated to offering prompt assistance and maintenance services, minimizing downtime and ensuring uninterrupted production.The application of CNC wood cutting machines extends beyond traditional woodworking, finding utility in diverse industries such as furniture manufacturing, cabinetry, and architectural millwork. The precision and versatility of these machines make them indispensable for creating custom designs and intricate patterns, meeting the ever-evolving demands of the market.As the global woodworking industry continues to evolve, {} remains committed to pushing the boundaries of innovation and technological advancement in CNC wood cutting machines. By leveraging its expertise and experience, the company strives to address the evolving needs of the woodworking industry by introducing new and advanced solutions that set new standards in precision, efficiency, and reliability.With a strong emphasis on quality, performance, and customer satisfaction, {} has established itself as a pioneer in the manufacturing of CNC wood cutting machines. The company's dedication to excellence and its relentless pursuit of innovation continue to drive the woodworking industry forward, setting new benchmarks and shaping the future of wood processing.In conclusion, the CNC wood cutting machines offered by {} represent a paradigm shift in woodworking technology, ushering in a new era of precision and efficiency. With their advanced features, unmatched accuracy, and versatile applications, these machines are poised to transform the woodworking industry, offering new possibilities for creativity and productivity. As the demand for high-quality, automated wood processing solutions continues to grow, {} remains at the forefront, leading the way with its cutting-edge CNC wood cutting machines.