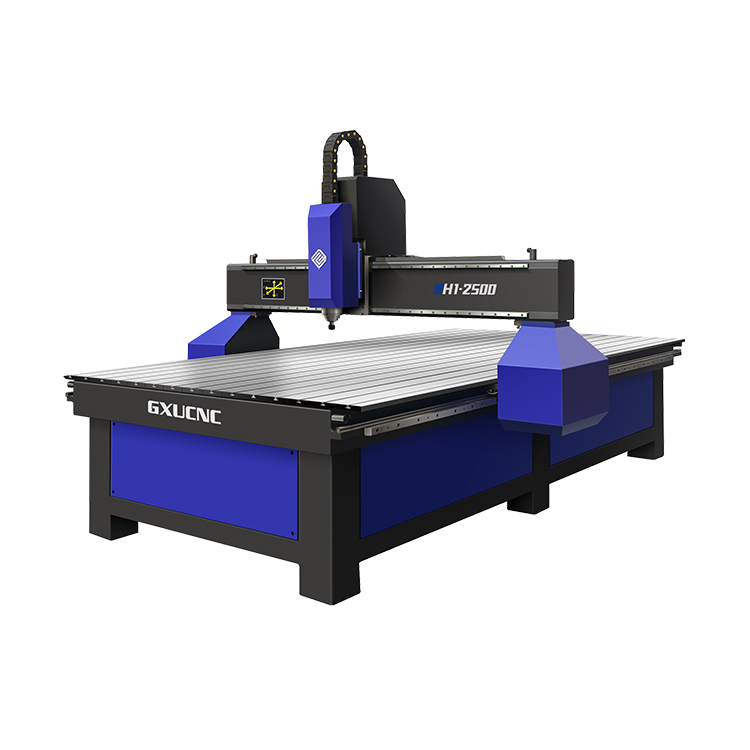

Maximizing Woodworking Efficiency with CNC Wood Engraving Machines

Title: Advanced CNC Wood Engraving Machine Redefines Precision and Efficiency in Woodworking IndustryIntroduction:The woodworking industry has constantly evolved with advancements in technology. One such breakthrough that has revolutionized precision and efficiency in woodworking is the state-of-the-art CNC Wood Engraving Machine. Developed by a leading company in the field (brand name omitted), this groundbreaking machine has undoubtedly raised the bar for wood engraving and carving processes.High Precision and Accuracy:The CNC Wood Engraving Machine boasts unparalleled precision and accuracy, ensuring flawless results in wood engraving. Equipped with cutting-edge technology, this machine utilizes computer programming and numerical control to produce intricate and detailed designs with utmost consistency. The advanced mechanisms and high-quality components of this machine guarantee minimal errors and smooth operations, resulting in exceptional output every time.Efficient Workflow:With its automated features and user-friendly interface, the CNC Wood Engraving Machine streamlines the woodworking process, significantly reducing human effort and time. The incorporation of computer-aided design (CAD) software allows designers and operators to conveniently create and modify designs seamlessly. Its fast and efficient production capability ensures that projects are completed in a fraction of the time compared to traditional woodworking methods, enhancing overall productivity and profitability for businesses.Versatility and Customization:One of the key advantages of the CNC Wood Engraving Machine is its versatility in accommodating a wide range of woodworking applications. From intricate designs on furniture to decorative patterns on doors and panels, this machine delivers exceptional results for various woodworking projects. Its ability to work with different types of wood, including hardwoods, softwoods, and composite materials, makes it a valuable asset for both small-scale workshops and large manufacturing facilities. Moreover, the machine's adaptability allows for customization, offering endless possibilities for personalized designs and unique creations.Enhanced Safety and Operator Comfort:This CNC Wood Engraving Machine prioritizes the safety and well-being of its operators. Equipped with advanced safety features, such as emergency stop buttons and protective barriers, it ensures a secure working environment. Additionally, the machine's ergonomic design takes into consideration the comfort of operators, mitigating strain and fatigue during prolonged use. These combined safety and comfort features not only safeguard the operators but also contribute to increased productivity and higher-quality output.Eco-friendly Operations:In an era where environmental sustainability is paramount, the CNC Wood Engraving Machine stands out as an eco-friendly solution. The machine utilizes modern energy-efficient technologies, reducing power consumption and minimizing environmental impact. Furthermore, its precise cutting capabilities minimize material wastage, optimizing resource utilization and promoting sustainability in the woodworking industry.Training and Technical Support:To ensure seamless integration and maximum utilization of the CNC Wood Engraving Machine, the company (brand name omitted) provides comprehensive training programs and technical support. Knowledgeable experts offer guidance on programming, operation, and maintenance of the machine, enabling users to unlock its full potential. Ongoing assistance and upgrades ensure that clients stay up-to-date with the latest advancements in this rapidly evolving field.Future Advancements and Market Outlook:The CNC Wood Engraving Machine has revolutionized woodworking with its unmatched precision, efficiency, and versatility. As technology continues to advance, this machine is expected to witness continuous enhancements that further improve its performance and capabilities. With a growing demand for intricately designed and customized wood products, the market outlook for such advanced CNC machines remains highly promising.Conclusion:The CNC Wood Engraving Machine has established itself as a game-changer in the woodworking industry. Its precision, efficiency, versatility, and eco-friendly operations have propelled it to the forefront of wood engraving and carving processes. With the support of the company behind its development, this advanced machine is set to redefine woodworking standards and drive innovation in the industry for years to come.

Read More

Fastest 5000 Watt Laser Cutters for Sheet Metal Prototyping Equipment

The utilization of laser cutters has revolutionized the field of manufacturing, particularly in the realm of sheet metal prototyping. With this technology, intricate designs can be achieved with precision and accuracy, creating a high-quality end product that meets customer requirements. At Incodema, we are proud to offer our customers the latest in laser cutting technology- the 5000 Watt Laser Cutter.The 5000 Watt Laser Cutter is the fastest laser cutting machine available on the market. Our machine is equipped with two flying optic Mitsubishi lasers, renowned for their speed and accuracy. This state-of-the-art technology allows us to deliver high-quality laser cutting services with quick turnaround times.The 5000 Watt Laser Cutter is powered by a high wattage laser beam that is used to vaporize the material being cut. The material is then removed by a jet of gas, leaving a clean, precise cut that meets the exact specifications of the customer. This process is highly efficient and accurate, making it ideal for prototyping and production runs.As an industry leader, we understand the importance of delivering exceptional quality to our customers. Our laser cutters are designed to handle a wide range of materials, including stainless steel, aluminum, brass, and copper. We are constantly innovating to improve our processes, ensuring that our customers receive the best possible product.At Incodema, we have a team of skilled professionals who operate our 5000 Watt Laser Cutters. We take pride in their expertise and knowledge, and we work hard to create a culture of continuous improvement. We regularly invest in the latest equipment and technology, providing our team with the tools they need to deliver the highest quality products.In addition to our 5000 Watt Laser Cutter, we offer a comprehensive range of services, including laser welding, CNC machining, and prototyping. We pride ourselves on our ability to deliver exceptional products to our customers while providing them with excellent customer service.In conclusion, the 5000 Watt Laser Cutter is a game-changer in the field of sheet metal prototyping. At Incodema, we understand the importance of cutting-edge technology in delivering a superior end product, and our 5000 Watt Laser Cutter is just one example of our commitment to excellence. Contact us today to learn how we can help bring your project to life.

Read More

Top Quality 5-Axis CNC Router Machines Available in China

When it comes to manufacturing and production processes, precision and efficiency are two key factors that businesses must prioritize. This is where the 5 axis CNC router comes in. With its advanced capabilities and cutting-edge technology, this machine has revolutionized the way parts and products are manufactured.What is a 5 axis CNC router?A 5 axis CNC router is a machine tool that is used to create, shape, and cut materials such as wood, plastic, and metal. It is different from a conventional CNC router because it has the ability to move in five directions, which gives it the ability to create more complex shapes and designs. These directions include three linear axes (X, Y, and Z) and two rotary axes (A and B).How does a 5 axis CNC router work?A 5 axis CNC router works by using a computer program to control its movement and cutting direction. The program tells the machine where to move and how to cut, ensuring that the final product is precise and accurate. The machine is equipped with a cutting tool that rotates in different directions, allowing it to cut with precision and speed. It is also able to work with different materials, including wood, plastic, and metal.Advantages of using a 5 axis CNC routerThere are many advantages to using a 5 axis CNC router for your manufacturing processes. Some of these advantages include:1. Greater precision: The machine's advanced cutting technology ensures that the final product is precise and accurate, even when dealing with complex shapes and designs.2. Faster production time: With its ability to work in five directions, the 5 axis CNC router can cut and shape materials quickly and efficiently, leading to faster production times.3. More design options: The machine's flexibility allows for more design options, giving businesses greater creative freedom when creating parts and products.4. Improved efficiency: The machine's advanced technology and precision cutting capabilities ensure that material waste is minimized, improving efficiency and reducing costs.5. Increased profitability: With faster production times and greater efficiency, businesses can increase their profitability and competitiveness in the market.ConclusionIn conclusion, the 5 axis CNC router is a valuable tool for any business involved in manufacturing and production processes. With its advanced technology and cutting-edge capabilities, it can help businesses improve their efficiency, reduce costs, and increase profitability. If you are in the market for a reliable and efficient machine for your manufacturing processes, a 5 axis CNC router may be just what you need.

Read More

Limitations of Mini Desktop CNC Mills for Machining Parts at Home

The rise of the mini desktop CNC mill has revolutionized the way we approach machining tasks. These machines may not have the size and power of full-size milling centers, but they have proven to be reliable and versatile tools that can produce high-quality parts in a variety of materials.One of the biggest advantages of a desktop CNC mill is its size. These machines are compact and easy to set up, making them perfect for small workshops or home-based businesses. They also tend to be more affordable than their larger counterparts, which is great news for hobbyists and small-business owners on a tight budget.However, there are some drawbacks to consider before investing in a mini desktop CNC mill. The primary issue is its limited capability when it comes to machining hard materials like stainless steel. The lack of rigidity in these machines can lead to poor finishes and even tool breakage, which can be frustrating and costly.For this reason, it's important to choose a desktop CNC mill that is specifically designed for the materials you plan to work with. If you're interested in machining aluminum, for example, be sure to look for a machine that is capable of handling the specific demands of this material.Another factor to consider is the machine's spindle speed. Lower-end desktop CNC mills may not have the power necessary to achieve high-speed machining, which can limit your ability to work with tougher materials. Look for a machine with a high-quality spindle that can be dialed in for optimum performance.In summary, a mini desktop CNC mill can be a great investment for hobbyists and small-business owners who need a reliable and versatile machining tool. Just be sure to choose a machine that is suited to your specific needs and materials, and understand its limitations when it comes to machining harder materials. With the right machine and proper setup, you'll be able to produce high-quality parts with ease and efficiency.

Read More

High-Precision Fiber Laser Cutting Machine for Efficient Metal Processing

CNC Fiber Laser Cutting Machine: The Innovation in Metal Cutting TechnologyOver the years, different advancements in technology have been made for different industries. One of the biggest beneficiaries of technological advancements is the manufacturing industry, and specifically the metal cutting industry. With the introduction of CNC Fiber Laser Cutting machines, manufacturers can cut different kinds of metal materials with a high precision and speed like never before.CNC Fiber Laser Cutting machines have gained immense popularity in the manufacturing industry. Companies like Shandong Pengwo Laser Technology Co., Ltd. have been at the forefront of designing and manufacturing CNC Fiber Laser Cutting machines that are efficient, precise, and reliable. The machine uses a fiber laser generator and ball screw moving system that enable it to cut and punch different types of metal materials without compromising on quality.Features of CNC Fiber Laser Cutting Machines1. High Cutting Precision:CNC Fiber Laser Cutting Machines have a high cutting precision that enables them to deliver top-notch end products. The laser is transmitted through a fiber, which ensures that there is no loss of energy, and hence precision cutting is achieved. Whether you need to cut intricate designs or thick metals, CNC Fiber Laser Cutting Machines will deliver.2. High Speeds:The use of advanced fiber laser technology with ball screw moving systems enables CNC Fiber Laser Cutting machines to achieve high speeds while cutting, without compromising the precision. By increasing the production speed, your manufacturing process will become more efficient, and your business will be more profitable.3. Low Maintenance:One of the biggest advantages of installing CNC Fiber Laser Cutting Machines is its low maintenance. Since the laser is transmitted through a fiber, there is no need to adjust or maintain the laser optical path. In contrast, traditional laser cutting machines require frequent maintenance, which can be costly and time-consuming.4. Energy Efficiency:CNC Fiber Laser Cutting Machines have excellent energy efficiency compared to other traditional metal cutting methods. The advanced fiber laser technology used in these machines significantly reduces the amount of energy consumed, which in turn helps to lower your operating costs. It is an environmentally friendly cutting option with no emissions of harmful substances.5. Versatile:CNC Fiber Laser Cutting Machines can cut different types of metals, including steel, stainless steel, aluminum, copper, and brass. This versatility makes them indispensable in the manufacturing process as they offer a wide variety of options to cut different shapes and sizes of metal materials.Conclusion:CNC Fiber Laser Cutting Machines are the latest innovation in the metal cutting industry. They offer a plethora of features that make them indispensable to the manufacturing process. High precision, high speed, low maintenance, energy efficiency, and versatility are some of the unique selling points of CNC Fiber Laser Cutting Machines. By incorporating them into your manufacturing process, you will increase efficiency, profitability, and precision cutting. So, if you are looking for an efficient and reliable way to cut metals, CNC Fiber Laser Cutting Machines are definitely worth considering.

Read More

Everything You Need to Know About Fiber Laser Metal Cutting Machine

Fiber Laser Cutting Machines: Revolutionizing Metal Cutting IndustryWhen it comes to metal cutting, the process has come a long way from manual tools to computerized machining systems. One of the most significant developments in this field has been the advent of fiber laser cutting machines. These machines utilize fiber laser technology to cut through a wide range of metal surfaces, including steel, aluminum, copper, brass, titanium, and more.The fiber laser cutting machine uses a laser beam to melt and cut through metal. The beam is generated by a highly concentrated source of light, which is directed through a series of lenses and mirrors, finally focusing it onto the metal surface to be cut. As the laser beam collides with the metal, its energy is absorbed, causing the metal to melt and vaporize into a plasma state. This process continues until the beam has cut through the metal, resulting in a precise and accurate cut.Fiber laser cutting machines have significant advantages over earlier metal cutting technologies. For instance, they can achieve much higher cutting speeds and produce more intricate shapes than traditionally used cutting methods. They also consume less energy and emit substantially less heat and gases while operating. As a result, fiber laser cutting machines are more environmentally friendly and safer to use.One of the leading manufacturers of fiber laser cutting machines is the company that is known for producing high-quality industrial-grade machines with exceptional precision and reliability. The company specializes in the design and production of fiber laser cutting machines and provides comprehensive solutions for all types of metal cutting applications.This company's fiber laser cutting machines range from small desktop models for hobbyists and small businesses to large-format models used in industrial manufacturing. They feature advanced controller systems that allow users to manipulate designs and produce highly accurate cuts, which can be critical in fields such as aerospace, automotive, and medical industries.In addition to its superior technical features, the company has always emphasized safety as a top priority in its production process. Therefore, all its fiber laser cutting machines are equipped with advanced safety features, which include sensors to detect collisions and laser beam interruption. It's also fitted with fire and smoke detection systems that help prevent equipment damage and minimize the risk of fire, enhancing operational safety.Undoubtedly, there is no question that fiber laser cutting machines are revolutionizing the way metal cutting industries operate worldwide. The precision, speed, and versatility they offer is unmatched by any traditional cutting methods. With the advent of this technology, companies can reduce production costs, improve efficiency, and produce high-quality parts with better accuracy, which, in turn, helps them stay competitive in the global market.In conclusion, the fiber laser cutting machine has proven to be one of the most innovative and significant inventions that have been introduced in the metal cutting industry. As demand for this technology continues to grow, manufacturers like the brand, will continue to push the boundaries of innovation to ensure that the fiber laser cutting machine remains at the forefront of the metal cutting industry.

Read More

Tabletop Laser Welder with Cutting-Edge Technology and Engineering Features

Benchtop Laser Welder: The Future of Precision WeldingThe world of welding has seen a significant transformation over the years, with the introduction of innovative technologies such as the benchtop laser welder. This new welding technology has revolutionized the industry, providing precision, versatility, and speed in welding applications. In this blog, we will delve into the world of benchtop laser welder and explore its features, benefits, and applications.What is a benchtop laser welder?A benchtop laser welder, also known as a desktop laser welder, is a high-precision welding machine that utilizes laser technology to fuse metals together. Unlike traditional welding methods that use heat to melt and fuse metals, a laser welder uses a high-intensity laser beam to melt and bond the metals together. The precision and accuracy of a laser welder are unmatched, making it a popular choice for welding applications that require intricate and detailed work.Features of a benchtop laser welderBenchtop laser welders come in different models and designs, but they all share some common features that make them stand out from traditional welding machines. Some of the notable features of benchtop laser welders include:Precision: Laser welders offer unmatched precision and accuracy when compared to other welding methods. With a laser welder, you can control the spot size, energy density, and pulse duration, ensuring that the welding is done with the highest level of precision.Speed: Laser welders are fast and efficient, making them ideal for industries that require high-speed welding. With a laser welder, you can weld metals at a speed of up to 100 inches per minute, saving you time and money on production.Ease of use: Benchtop laser welders are easy to use, even for non-professionals. They come with intuitive controls and user-friendly interfaces that allow even the most novice users to operate them with ease.Benefits of a benchtop laser welderBenchtop laser welders offer numerous benefits that make them an ideal choice for welding applications. Some of the benefits of using a benchtop laser welder include:Improved quality: With a benchtop laser welder, you can achieve high-quality, consistent welds that are free from defects. Laser welding is a non-contact process, which means there is no risk of physical damage to the materials being welded, ensuring that the welded joints are of the highest quality.Versatility: Laser welders can weld various metals, including aluminum, copper, brass, and stainless steel. This makes them versatile for use in different industries, including automotive, aerospace, and medical device manufacturing.Cost-effective: Laser welding is a cost-effective welding method, as it requires less material and labor compared to traditional welding methods. The precision of laser welding reduces the need for post-welding finishing, saving you money on production costs.Applications of a benchtop laser welderBenchtop laser welders are versatile tools that find applications in various industries. Some of the applications of benchtop laser welders include:Jewelry and watchmaking: Laser welders are popular in the jewelry and watchmaking industry due to their precision and accuracy. They are used to weld tiny components, such as clasps, chains, and watch dials.Automotive industry: Benchtop laser welders are used to weld small components in the automotive industry, such as sensors, connectors, and electrical systems.Medical device manufacturing: Benchtop laser welders are used in the medical device manufacturing industry to weld small components in medical devices, such as stents and catheters.ConclusionBenchtop laser welders are the future of welding. They provide precision, versatility, and speed, making them an ideal choice for different industries. The benefits of using benchtop laser welders, such as improved quality and cost-effectiveness, make them an attractive option for businesses looking to optimize their production processes. If you're in the market for a welding machine, consider investing in a benchtop laser welder for high-quality, consistent welds in your production line.

Read More

Laser Cutting Job Opening in Dudley, UK: Apply Now with ASC Connections!

If you're looking for a job in the engineering and manufacturing sectors, then the Laser Cutter job with ASC Connections Ltd could be the perfect opportunity for you. Located in Dudley, UK, this job is ideal for those who have experience in using steel laser cutters and are looking for a challenging and rewarding role.The use of laser cutters is becoming increasingly popular in the engineering and manufacturing industries due to their accuracy, speed, and versatility. Steel laser cutters can cut through a variety of materials, including steel, aluminum, and copper, making them an essential tool for producing precision parts and components.As a Laser Cutter with ASC Connections Ltd, you will be responsible for operating and maintaining the steel laser cutter to produce high-quality parts. You will be required to read and follow technical drawings and specifications, and have a good understanding of CNC programming. You may also be required to carry out minor repairs and adjustments to ensure the laser cutter is operating at maximum efficiency.To be successful in this role, you will need to have experience in using steel laser cutters, a good understanding of engineering principles, and excellent attention to detail. You will also need to be a good communicator and work well as part of a team.This Laser Cutter job with ASC Connections Ltd offers an excellent salary package and opportunities for career development within the company. You will be working in a modern and well-equipped manufacturing facility, alongside a team of experienced engineers and technicians.If you're looking to take your career in the engineering and manufacturing industries to the next level, then this Laser Cutter job with ASC Connections Ltd could be the perfect opportunity for you. Apply today and take the first step towards a challenging and rewarding career in this exciting sector.

Read More

Powerful 1500mmx3000mm Fiber Laser Cutting Machine with options of 500w, 700w, and 1000w Laser Sources: Efficient and Precise Cutting Technology

Co2 Laser Cutting Machine 500w: The Best Choice for High-Quality CuttingCutting metal, plastics, wood, and other materials often used in construction, manufacturing, and industrial applications is a challenge without a laser cutting machine. Though many types of laser cutting machines are available, the Co2 Laser Cutting Machine 500w stands out for its unparalleled efficiency, reliability, and quality.A Co2 Laser Cutting Machine is a highly efficient, yet affordable cutting tool that uses a mixture of gases and a focused beam of laser energy to cut through metals and other tough materials. The 500w laser source is perfect for small businesses and startups looking to cut materials with precision and high-quality results.Compared to traditional cutting methods, Co2 Laser Cutting Machines are faster, more accurate, and require lower maintenance. The fiber transmission used in this cutting machine guarantees a consistent quality cutting effect in every point of the material being cut. The technology has been specially designed to reduce gas consumption and increase photoelectric conversion efficiency, which can reach up to 35%.The 1530 fiber cutting machine 500w is a high-performance machine that can cut through a wide range of materials, including steel, stainless steel, aluminum, brass, copper, and other non-metal materials such as acrylic and plastics. The machine's accuracy is excellent, and the use of fiber transmission ensures a consistent and reliable cutting result.The Co2 Laser Cutting Machine 500w is also an excellent tool for precise cutting of intricate geometric patterns. The machine's cutting speed is fast, and the exactitude is exceptional at every point. Plus, the machine's software can be programmed to cut almost any shape or design that you need, or you can simply upload your design, and it will automatically start cutting.With the ability to cut materials of varying thicknesses, Co2 Laser Cutting Machines are versatile and can be used for various projects in different industries. Additionally, the cutting machine has excellent cutting capacity and high processing quality. And, because of these characteristics, the machines are ideal for particular industries, including building and construction, automotive, and other manufacturing industries requiring high precision cuttings.In summary, the Co2 Laser Cutting Machine 500w is an excellent choice for cutting through a wide range of materials with high precision and accuracy. The machine not only saves time but also minimizes material wastage and guarantees high-quality results. Whether you are in the manufacturing, automotive, or construction industry, this machine can help you achieve your goals and realize the full potential of your business.

Read More

CNC Cutting Machine Manufacturers and Suppliers in China - Seek Cooperation for Mutual Benefits

The world of manufacturing is constantly evolving to keep up with the demands of customers. One innovation that has revolutionized the manufacturing industry is Computer Numerical Control (CNC) machines. These machines use computer-aided software to operate and control the movements of precision cutting tools that cut through various materials, including steel. CNC steel cutting machines have become increasingly popular in industrial settings due to their precision, speed, and efficiency.At Qianyi Steel CNC Cutting Machine Manufacturers in China, we are committed to producing high-quality and reliable CNC steel cutting machines that meet the needs of our customers. Our machines are designed to offer maximum performance, accuracy, and speed, making them ideal for a wide range of industrial applications.One of the primary benefits of CNC steel cutting machines is their ability to produce consistently precise cuts. The computer-controlled machines are programmed to follow specific cutting patterns, and the cutting tools are designed to cut through materials with extreme accuracy. This precision is particularly critical in manufacturing, where even small deviations in cutting can lead to significant production issues.Another significant advantage of CNC steel cutting machines is speed. These machines can cut through steel much faster than manual cutting methods, making them an ideal option for large-scale industrial operations. Additionally, CNC machines can operate for extended periods without the need for frequent maintenance, ensuring consistent performance and reliability.At Qianyi Steel CNC Cutting Machine Manufacturers, we believe in delivering customized solutions to meet your specific requirements. We offer a wide range of CNC steel cutting machines, including plasma cutters, laser cutters, waterjet cutters, and flame cutters, ensuring that you can find the machine that best meets your needs.In conclusion, CNC steel cutting machines offer manufacturing companies a range of benefits, including precision, speed, and efficiency. As a leading manufacturer of these machines, Qianyi Steel CNC Cutting Machine Manufacturers is committed to providing our customers with high-quality equipment that meets their specific needs. Contact us today to learn more about our products and services and see how we can help improve your manufacturing operations.

Read More